To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-22

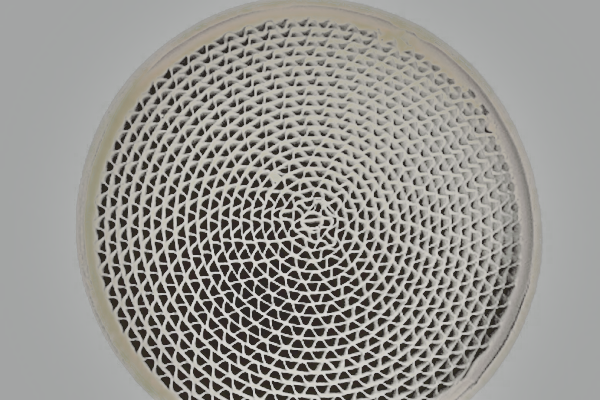

Honeycomb structure is used in catalytic converter substrate for flow control and surface area management. Structure consists of straight parallel channels arranged in a uniform pattern. Exhaust gas flows through channels without directional change. Flow behavior remains stable across the substrate cross section. Turbulence is limited at the inlet face. Gas distribution is more uniform compared with non-channel structures.

Cell density defines channel count per unit area. Higher cell density increases catalyst surface area and reaction efficiency. Pressure drop increases accordingly. Lower cell density reduces flow resistance and back pressure. Catalyst contact area is reduced. Selection is based on exhaust mass flow, target emissions, and available installation volume.

Wall thickness affects thermal response and mechanical strength. Thin walls heat up faster and support early catalyst activation. Structural margin is reduced under vibration and thermal cycling. Thicker walls improve durability and resistance to deformation. Thermal mass and pressure loss increase. Wall thickness is matched to operating temperature range and vibration level.

Honeycomb structure is applied in metallic and ceramic catalytic converter substrate designs. Metallic substrates use thin metal foil, commonly FeCrAl alloy, formed into corrugated layers. Good thermal conductivity. High vibration tolerance. Suitable for rapid temperature change. Ceramic substrates use extruded structures. Higher thermal stability under steady conditions. Lower tolerance to mechanical shock.

Straight channel geometry supports uniform temperature distribution on the catalyst surface. Local hot spots are reduced. Coating aging remains more consistent across the substrate face. Conversion efficiency remains stable over service life.