To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-23

Industrial and automotive catalytic converters are designed for different operating environments. The basic reaction principle is the same, but system requirements are not.

Automotive catalytic converters operate under highly variable conditions. Engine speed and load change frequently. Exhaust temperature fluctuates. Cold start performance is critical. Converter volume is limited by vehicle packaging. Weight and fast light-off are key design targets.

Industrial catalytic converter are used in stationary or semi-stationary systems. Engines, generators, boilers, and turbines run at steady load for long periods. Exhaust temperature is higher and remains stable. Exhaust flow rate is significantly larger. Converter size is defined by flow capacity rather than space constraints.

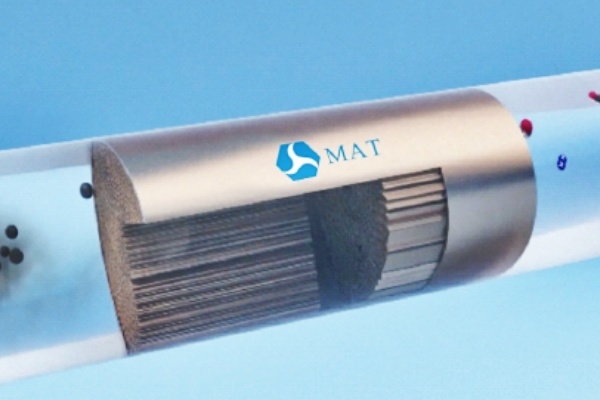

Substrate selection differs. Automotive systems commonly use ceramic or metallic substrates optimized for quick heat-up and cost control. Industrial catalytic converter use metallic substrates or heavy-duty ceramic substrates selected for thermal stability, oxidation resistance, and long service life. Rapid light-off is less critical than durability.

Mechanical design also differs. Automotive converters must withstand road vibration, shock, and frequent thermal cycling. Industrial converters are designed for continuous operation, high thermal load, and long exposure time. Housing strength, support structure, and expansion allowance are critical.

Service expectations are not the same. Automotive catalytic converters are designed around vehicle lifetime requirements. Industrial catalytic converter are expected to operate for thousands of hours. Maintenance access, inspection, and replacement strategy are part of the system design.

Control strategy is different. Automotive converters operate as part of a closed-loop system with sensors and ECU control. Industrial catalytic converter are tuned for fixed operating conditions. Emission performance is defined during system design rather than adjusted dynamically.

The difference between industrial and automotive catalytic converters is driven by operating conditions, scale, and durability requirements, not by catalytic chemistry.