To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-06

In many systems, airflow is never as clean as people imagine.On drawings and simulations, the flow looks smooth. But in reality, once air goes through a fan, a bend, a sudden expansion, or a valve, it usually becomes unstable. You get swirl, uneven velocity, and pressure variations. Sometimes the problem is obvious. Other times, everything looks normal from the outside, but the data tells a different story.

That’s usually when a honeycomb straightener starts to make sense.

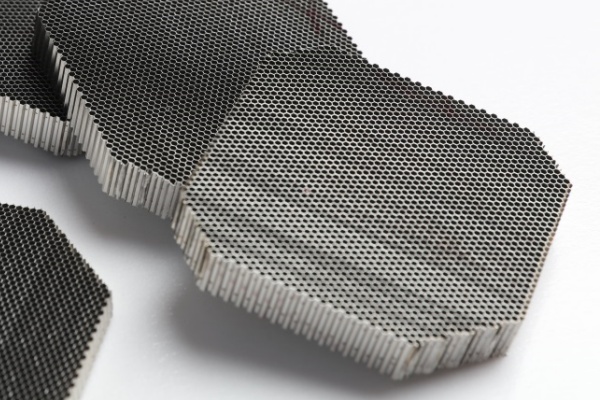

A honeycomb straightener is not a complicated device. Structurally, it is made up of many small, straight channels placed next to each other. When airflow passes through these narrow paths, the sideways movement is naturally reduced. The air is almost forced — gently — to move in one direction only.

There’s no magic in it. No moving parts. No energy input. Just geometry doing its job.

As the disturbed airflow enters the straightener, it is divided into dozens or even hundreds of smaller streams. Inside each channel, the air has less room to move randomly. The swirling dies down, and the velocity profile becomes more consistent by the time it exits the other side.

That is exactly why honeycomb straightener designs are widely used in wind tunnels, test benches, ventilation systems, exhaust lines, and emission measurement setups. When accurate and stable flow is required, straightening becomes a basic but critical step.

In practice, the performance of a honeycomb straightener depends a lot on its geometry. Short cells don’t have enough length to fully calm the flow. Extremely small cells can improve straightening, but they also increase resistance and pressure drop. So there is always a balance. Engineers usually choose the cell size and length based on how much correction is needed and how much pressure loss the system can accept.

Material is another factor people often overlook.

In high-temperature or corrosive environments, plastic or soft metals won’t last long. That’s why stainless steel or FeCrAl alloy honeycomb straighteners are commonly used in industrial and exhaust applications. These materials can handle heat, vibration, and oxidation without deforming or breaking down over time.

For lighter-duty applications, aluminium or engineered polymers may be enough. They reduce weight and cost while still providing a noticeable improvement in flow quality.

Even though a honeycomb straightener may look like a simple insert, it often has a big impact. Flow meters read more accurately. Sensors behave more consistently. Catalytic elements receive a more even distribution of gas. The whole system becomes more predictable.

In many projects, it is one of those parts that is easy to ignore at the design stage, but once it’s added, the difference is immediately visible in the data.And usually, after that, it becomes impossible to leave it out again.