To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-05

When people talk about diesel emission control, most of the attention goes to the catalyst coating or the emission standard itself. But in reality, one of the most important parts of a DOC is the structure underneath the catalyst — the DOC Metal Substrate.

Without a proper substrate, even the best coating won’t perform well, especially in real industrial conditions.

A DOC, or Diesel Oxidation Catalyst, is designed to deal with gases like carbon monoxide (CO) and unburned hydrocarbons (HC) that come out of a diesel engine. As the hot exhaust flows through the catalyst, these harmful gases are oxidized into less problematic substances, mainly carbon dioxide and water.

The job of the metal substrate is to create the right environment for that reaction to happen — over and over again, for thousands of hours.

So what exactly is a DOC Metal Substrate?

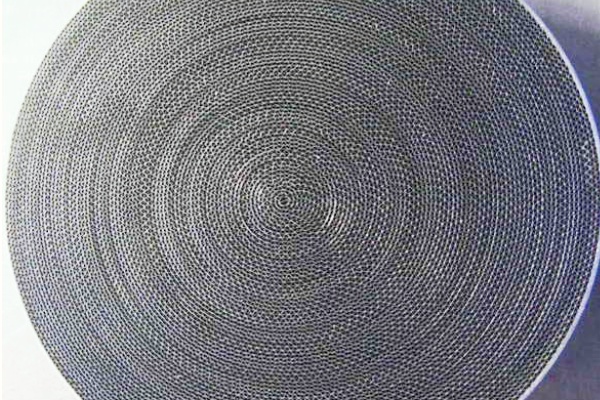

In simple terms, a DOC Metal Substrate is a thin metal structure formed into a honeycomb shape. It is usually made from a Fe-Cr-Al alloy, which can survive very high temperatures and resist oxidation.

Inside this honeycomb, there are thousands of narrow channels. These channels give the exhaust gas a large surface area to touch the catalyst coating. More contact means better conversion efficiency.

At the same time, the metal itself heats up very fast. Compared to ceramic materials, metal brings the catalyst to its working temperature much quicker. This is especially useful when an engine is started cold or runs at low load.

What happens inside when the engine is running?

When a diesel engine is operating, the exhaust gas enters the DOC and flows through the metal channels.

The metal substrate heats up almost immediately. As the gas moves through the narrow passages, it comes into direct contact with the catalyst on the channel walls. That is where the oxidation of CO and HC takes place.

Because the structure is metal, it can also handle vibration, pressure pulses, and temperature swings much better than a ceramic alternative. That is why metal substrates are often chosen for applications that involve rough conditions, such as:

Construction machinery

Agricultural equipment

Marine engines

Generators and heavy-duty vehicles

In these environments, stability is just as important as efficiency.

Why many systems prefer metal over ceramic

Ceramic substrates have been used for years and still work well in many passenger vehicles. But once you get into high load, high vibration, or long working hours, their limitations become more obvious.

Metal substrates are tougher. They don’t crack as easily under thermal shock. They are more flexible when it comes to design. Wall thickness can be controlled more precisely, and flow characteristics can be optimized for specific applications.

Another practical advantage is durability. For industrial engines that are expected to run day and night, downtime is expensive. A well-designed DOC Metal Substrate helps extend the working life of the entire aftertreatment system.

Design choices make a big difference

Even with the same material, not all metal substrates perform the same.

Things like:

cell density

foil thickness

channel geometry

overall size

all affect how the DOC behaves in the system. Too dense, and backpressure increases. Too open, and efficiency drops. Too thin, and durability becomes an issue.

That is why most professional suppliers don’t just sell a “standard part”. They evaluate the engine size, exhaust temperature, flow rate and emission target before selecting or designing the substrate.

A part you don’t see, but definitely need

The DOC Metal Substrate sits quietly inside the converter housing. You don’t see it, and most end users never think about it. But it directly affects start-up behavior, emission levels, fuel efficiency and system reliability.

If it is not chosen properly, the whole emission system suffers. If it is chosen well, everything else works more smoothly.

In a way, the metal substrate is the foundation of a good DOC system — not the most visible part, but one of the most important ones.