To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-17

Choosing a metal substrate always sounds straightforward on slides, but in real work it rarely is. Once the part goes into the system, it has to survive heat, vibration, corrosion, and dozens—sometimes hundreds—of thermal cycles without warping or shedding its coating. After running into enough problems on emission and VOC projects, I started keeping a simple checklist. Here’s the version I share with colleagues.

My first question on any new project is always the same:

How hot does it get?

How stable is the duty cycle?

Any salt spray or humidity concerns?

Diesel DOC / high-temperature, heavy cycling:

FeCrAl is almost always the safest choice. Its oxide layer grows and regenerates, and it handles long-term thermal aging better than stainless.

Gasoline / VOC systems with milder temperatures:

304 or 316L can be enough, especially when budget pressure is real.

If the unit sits near the coast or outdoors for long periods, go straight to FeCrAl. It simply lasts longer.

Some customers love to jump to 400 or 600 CPSI as if denser automatically means better. Anyone who has tuned a system knows the truth:

too high a CPSI and backpressure kills you long before the catalyst lights off.

Rough guide:

100–200 CPSI: low pressure drop, limited surface area

300–400 CPSI: the practical sweet spot; most DOC metal substrates fall here

600+ CPSI: only when packaging is extremely tight

Specs on paper don’t mean much unless the overall system can take the pressure drop and still meet light-off requirements.

Foil thickness is one of the first things we check.

Thin foil (0.03–0.05 mm):

Heats up quickly, but vibration resistance is mediocre.

Thick foil (0.06–0.1 mm):

Much better mechanical strength, but slower thermal response.

Anyone who has worked with NRMM or construction machinery knows how brutal the vibration can be. Thin foil may look nice in the lab, but in the field it can deform within a few hundred hours.

Corrugation angle and depth also matter. If the corrugation doesn’t distribute flow properly, even the best material won’t save it.

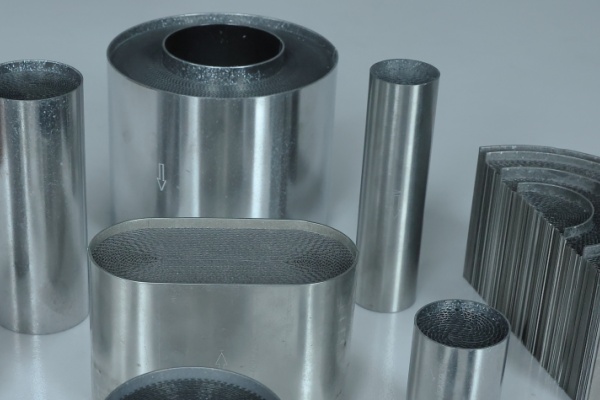

From a durability standpoint, round substrates are the most stable and vibration-resistant.

Round: best for vibration

Oval: compromise when space is limited

Rectangular: more common in industrial VOC systems

Most of the time, the shape isn’t chosen by design preference—it’s dictated by what survives durability testing.

Coating failure is one of the most common problems.

Based on field experience:

FeCrAl’s natural oxide layer is more coating-friendly.

Stainless steel can work, but if the pre-treatment isn’t done properly, the coating starts peeling after a few thermal cycles.

Many teams read the material data sheet but ignore the surface prep process, which ends up being the real cause of failure.

This is the part many people underestimate:

material choice is only half the story; manufacturing quality is the other half.

In inspections we usually check:

corrugation collapse

weld consistency

coating thickness variation

warping after thermal aging

channel alignment

brazing temperature control

All of these determine whether the substrate will survive the required life.

Choosing a metal substrate isn’t about who has the best data sheet or the lowest price.It’s about whether the part can survive the real duty cycle:

heat, vibration, coating adhesion, pressure drop, corrosion, and long-term durability.

If you keep those factors in mind, it’s hard to go wrong.