To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-18

In emission control systems, the DOC metal substrate is one of those components that rarely gets attention outside the engineering circle, yet it decides whether the whole aftertreatment setup performs the way it should. For a diesel oxidation catalyst (DOC), the substrate is essentially the backbone. It carries the catalytic coating, guides the exhaust flow, and takes the full impact of heat, vibration, and constant thermal cycling. If the substrate fails, the catalyst doesn’t stand a chance.

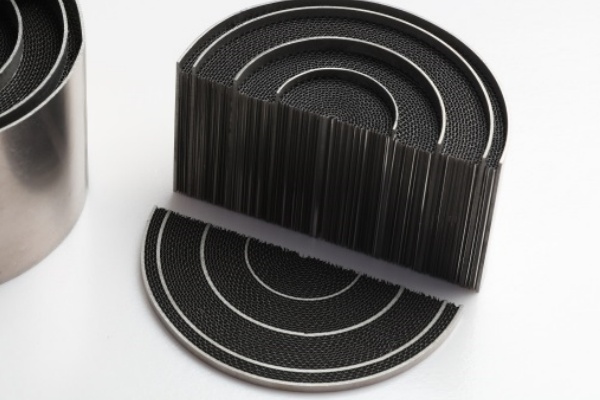

Although it looks like a simple metal cylinder when installed in the can, the structure inside is anything but simple. A DOC metal substrate starts as thin stainless-steel or FeCrAl alloy foil. These strips are corrugated, layered, and tightly wound to form a honeycomb body. Engineers like this configuration because it creates hundreds of parallel channels—just enough surface area to hold the catalytic washcoat without choking the exhaust flow. Whether the engine belongs to a small construction loader or a heavy-duty long-haul truck, the idea stays the same: the substrate needs to survive, and it needs to stay stable for thousands of operating hours.

One of the main reasons DOC systems favor metal substrates is temperature. Diesel exhaust can heat up fast and cool down just as quickly. Ceramic substrates take longer to warm up, but metal reaches reaction temperature much sooner. This matters because catalytic activity depends heavily on what we call “light-off”—the point where the catalyst becomes effective. A DOC that lights off early helps reduce CO and HC emissions, especially during cold starts, low-load operation, or frequent load transitions. Metal substrates react quickly to these temperature swings and resist cracking or breaking when the engine vibrates or bounces around in mobile equipment.

Inside those narrow channels, the real chemistry takes place. The substrate itself doesn’t perform the reaction; the washcoat on the surface does the work. This coating—often loaded with platinum or palladium—creates the active sites where CO and hydrocarbons oxidize into CO₂ and H₂O. When exhaust enters the DOC metal substrate, the flow splits across hundreds of channels, hugging the coated walls long enough for the reaction to happen. If the channels are too dense, backpressure increases. If they’re too open, the reaction surface area drops. The right balance depends entirely on the engine’s displacement, exhaust temperature patterns, and how strict the emission regulations are for that application.

Durability is one of the main considerations when selecting or designing a DOC metal substrate. A diesel engine doesn’t offer a gentle environment. Vibration is constant, especially in non-road equipment like excavators, loaders, tractors, and mining machines. Metal foils that are too thin tend to deform after prolonged vibration or repeated heat cycles. Foils that are too thick warm up slowly, delaying the chemical reaction. Engineers spend a surprising amount of time adjusting foil thickness, corrugation geometry, and CPSI—not to chase numbers, but to avoid downstream issues like catalyst loss, channel collapse, or increased backpressure after long-term use.

Material choice also plays a big role in the longevity of a DOC metal substrate. FeCrAl alloys tend to grow a stable oxide layer under high heat, which improves washcoat adhesion and long-term thermal resistance. Stainless steel grades, on the other hand, can work for applications with lower operating temperatures or where cost pressure is high. But in high-heat diesel applications—particularly where regeneration events or sudden spikes occur—the FeCrAl option usually proves its worth. This difference becomes obvious after durability testing: metal substrates that rely on stainless steel may warp or lose coating adhesion over repeated cycles, while FeCrAl versions stay intact much longer.

Another important aspect of DOC metal substrate performance is how well it manages exhaust flow. Every DOC design must meet conversion targets without introducing excessive pressure drop. A substrate that’s too restrictive can hurt engine response, increase fuel consumption, and cause overheating issues upstream. Testing often reveals that two substrates with identical CPSI can behave very differently depending on their corrugation pattern, foil stiffness, and precision of the winding process. Small imperfections like channel misalignment or uneven brazing can create turbulence, hotspots, or flow distortion inside the catalyst. In practice, this means the manufacturing quality of the substrate affects performance just as much as the design.

When engineers evaluate whether a DOC system has done its job, they usually look at long-term stability rather than short-term performance. A brand-new substrate can look perfect in initial tests, but the real question is what it will look like after 1500 or 3000 hours of operating in dust, vibration, moisture, and varying loads. A poorly designed or poorly manufactured metal substrate might show signs of foil fatigue, crack propagation, or coating flaking. Once the washcoat begins to detach, the catalyst loses efficiency fast. This is why many emission system suppliers run aggressive thermal shock and vibration tests before approving a DOC metal substrate for production use.

At the system level, the DOC metal substrate influences more than just oxidation reactions. It affects downstream components too—DPFs, SCR catalysts, and ammonia slip catalysts. If the substrate doesn’t heat up properly, the DPF may not regenerate efficiently. If the flow distribution becomes uneven, the SCR might receive exhaust that is either too hot, too cold, or too oxygen-rich. In modern engine platforms, everything depends on everything else, which is why the substrate is not a small detail but a foundation component.

Ultimately, understanding how a DOC metal substrate works is less about memorizing definitions and more about respecting the conditions it must survive. It has to manage exhaust flow, tolerate harsh environments, hold a coating reliably, and maintain geometry over years of operation. When it does all that, the DOC behaves predictably, emissions stay under control, and the engine can run efficiently without hidden penalties.

For engineers who work on emission systems every day, the DOC metal substrate isn’t just another part. It’s the difference between a system that performs reliably and one that becomes a maintenance problem. And in an industry where emission limits grow tighter each year, getting this component right is more important than ever.