To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-14

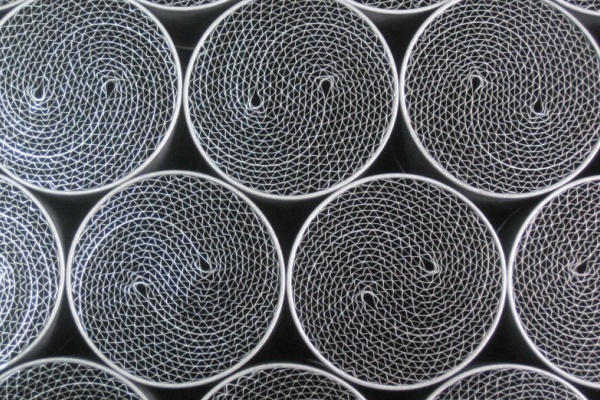

Working with DOC metal substrate every day teaches you that the honeycomb channel design isn’t just a small detail—it controls how the whole catalyst performs. From heavy-duty trucks to marine engines, the way gases flow through the substrate determines how efficiently CO, hydrocarbons (HC), and NOx get converted.

In the lab and on the test bench, we’ve seen the difference even a minor change in channel shape can make. Round channels tend to provide uniform flow and fewer hotspots. Square or irregular channels sometimes create areas where gas moves too fast or too slow. That’s a big deal because uneven flow can damage the coating or reduce conversion efficiency.

Pore size is just as critical. We’ve tested substrates where changing the cell diameter by fractions of a millimeter noticeably improved CO and HC conversion. It’s a balancing act: small pores increase contact time but can raise backpressure, which the engine doesn’t like.

Wall thickness isn’t just for strength—it affects flow, heat transfer, and vibration resistance. Thicker walls help the substrate survive thermal cycling and engine vibration, especially in off-road machinery or marine environments. On the other hand, thicker walls reduce open area, slowing gas flow and light-off during cold starts.

In our experience, optimizing thickness section by section works best: slightly thinner walls in the DOC zone for quicker light-off, slightly thicker walls downstream to handle exhaust loads and maintain structural integrity.

Engines don’t run like lab simulations. Temperatures fluctuate, flow is uneven, and vibration constantly shakes the system. That’s why CFD simulations combined with field testing are crucial. We’ve found that small tweaks—like slightly tapered channels or adjusting cell density—can improve flow uniformity and prevent local overheating.

A round metal substrate has to maintain its shape under these conditions. Any warp or misalignment affects gas contact with the catalyst and reduces efficiency. That’s something you only notice when you see a substrate after several thousand hours of operation.

We’ve pulled substrates out of failed units and traced the problems back to design details: uneven channels, inconsistent wall thickness, or weak brazing joints. These cause cracks, coating delamination, and ultimately lower CO/HC conversion. Paying attention to these “small” things during design and production saves a lot of headache in the field.

Channel shape, pore size, and wall thickness define what a DOC metal substrate can do. Get them right, and you balance conversion efficiency, backpressure, and durability. From our perspective as engineers working with these systems every day, a well-designed substrate isn’t flashy—it just works, reliably, engine after engine.