To be a valuable global supplier

for metallic honeycombs and turbine parts

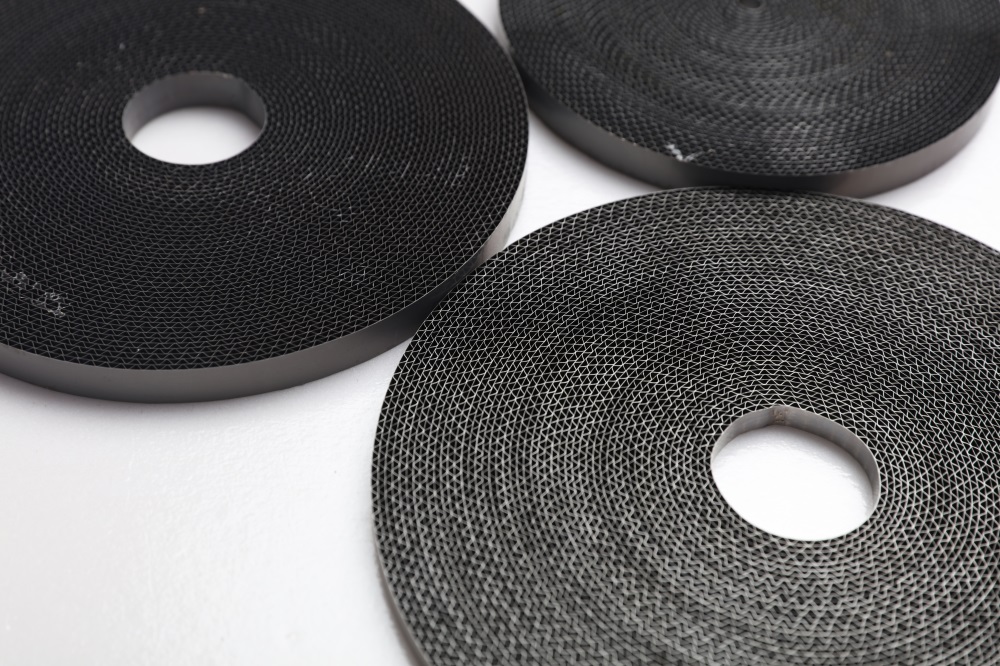

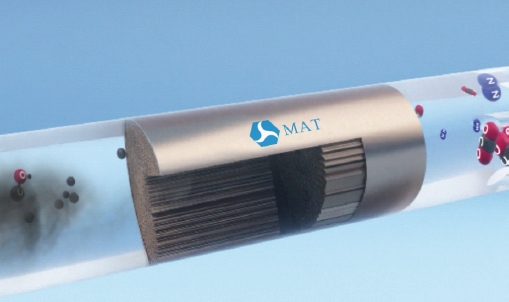

The metal substrate is formed by pressing and curling metal foil into honeycomb structure, then placing it in ametal shell and brazing it. It is mainly used for waste gas treatment of automobiles, motors, general machinery, machinery, and heavy industry.

Compared with the ceramic substrate, the metal substrate not only has the advantages of longer service life, heat resistance and vibration resistance, but also has the characteristics of small thermal melting and high thermal conductivity, which can shorten the catalyst heating time during the cold start of the car and improve the start-up efficiency of exhaust gas purification, so as to better achieve the goal of low-carbon environmental protection.

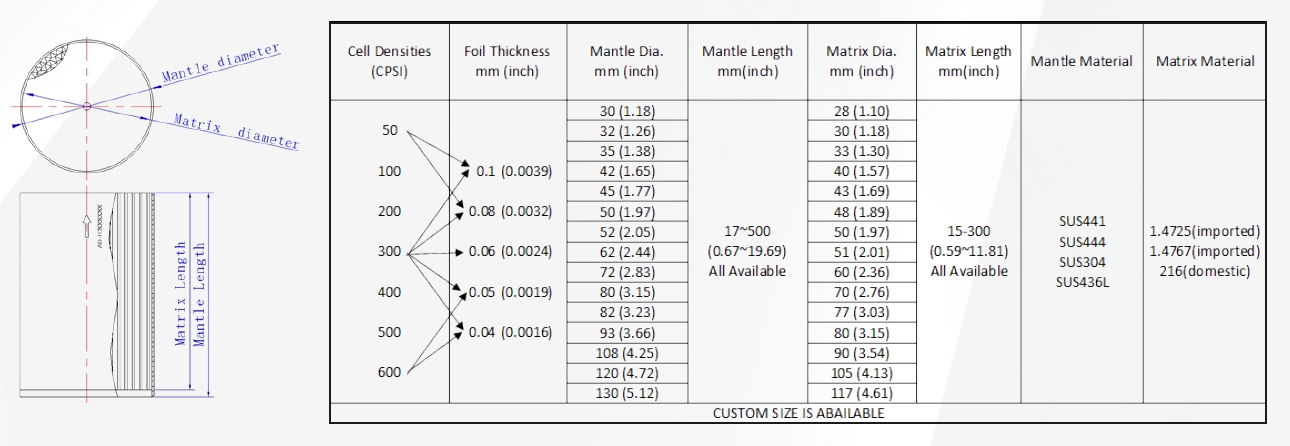

MAT has more than 5 years of experience in metal substrate manufacturing. We not only provide customers with metal substrates in different shapes, such as round, oval, rectangular, polygonal, etc., but also meet customers' different needs for cell density (CPI). In order to meet the different needs of domestic and foreign customers, our products comply with Euro II ~ Euro V emission standards, EPA, CARB standards, and become an important part of "reducing carbon emissions and cleaning the air".

MAT's metal substrates are used in different fields:

Small Substrate:

Auto parts

Garden equipment

Motorcycle accessories

Off-road equipment

Aviation filtration

Large Substrate:

Diesel generators

Power generation equipment

Oil and gas pumping stations