To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-06-23

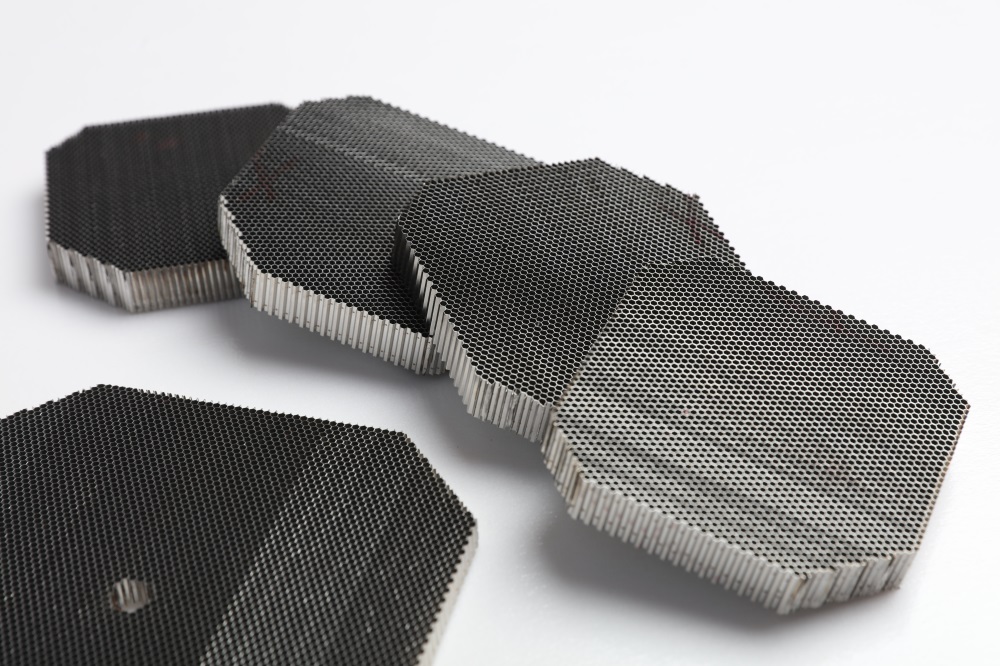

The Catalytic Converter Metal Honeycomb Substrate for Cars/Motorcycle plays a critical role in reducing harmful emissions by facilitating catalytic reactions. Among its key structural parameters, cell density (cells per square inch, CPSI) and wall thickness significantly influence conversion efficiency. Understanding their impact helps optimize performance while balancing pressure drop and durability.

Higher cell density in the Catalytic Converter Metal Honeycomb Substrate for Cars/Motorcycle increases the available surface area for catalytic reactions, improving conversion efficiency. However, excessively dense structures may cause higher backpressure, reducing engine performance. A moderate cell density (e.g., 400–600 CPSI) is often preferred to balance efficiency and flow dynamics.

Thinner walls in the Catalytic Converter Metal Honeycomb Substrate for Cars/Motorcycle enhance heat transfer and reduce thermal inertia, leading to faster light-off times. However, ultra-thin walls may compromise mechanical strength, risking substrate damage under vibration or thermal stress. Manufacturers must strike a balance between durability and catalytic responsiveness.

The interplay between cell density and wall thickness determines the overall effectiveness of the Catalytic Converter Metal Honeycomb Substrate for Cars/Motorcycle. Optimized designs ensure efficient pollutant conversion (CO, HC, NOx) while maintaining engine efficiency and substrate longevity.

The Catalytic Converter Metal Honeycomb Substrate for Cars/Motorcycle relies on carefully engineered cell density and wall thickness to maximize emission control. Future advancements may focus on novel materials and geometries to further enhance performance under stringent environmental regulations.