To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-06-24

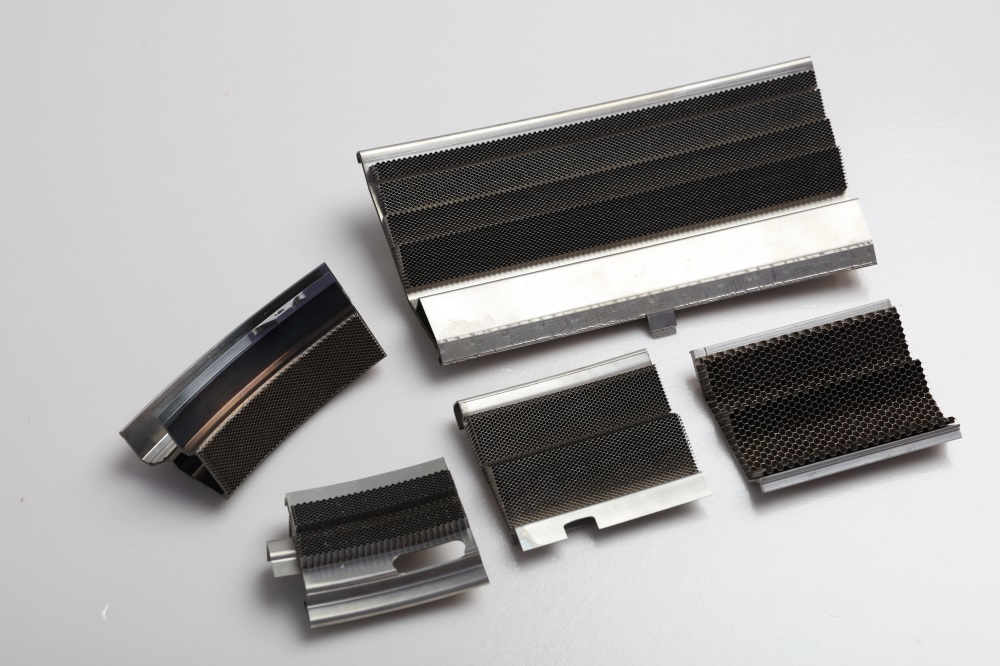

The Honeycomb Metal Substrate Catalytic Converter with Coating represents a breakthrough in emission control technology. Combining structural efficiency with advanced catalytic materials, this solution enhances pollutant conversion while maintaining durability. Its unique design and functional coatings make it indispensable in modern exhaust treatment systems.

The Honeycomb Metal Substrate Catalytic Converter with Coating leverages metal alloys (e.g., Fe-Cr-Al) to achieve superior heat transfer, enabling faster catalyst activation at low temperatures compared to ceramic counterparts.

Its welded honeycomb structure resists vibration and thermal shock, making it ideal for heavy-duty vehicles and harsh operating conditions.

Precious metal coatings (Pt/Pd/Rh) are uniformly applied via washcoating, maximizing surface area for NOx, CO, and HC reduction while minimizing precious metal usage.

The open frontal area of the honeycomb geometry reduces exhaust flow resistance, improving engine efficiency without compromising conversion rates.

The Honeycomb Metal Substrate Catalytic Converter with Coating is widely adopted in gasoline and diesel vehicles, meeting Euro 7 and China VI emission standards through efficient cold-start performance.

Stationary engines and generators utilize this technology to abate particulate matter and gaseous pollutants in compliance with environmental regulations.

Its corrosion-resistant coatings and robust structure suit marine engines and construction machinery exposed to saline or dusty environments.

The rapid thermal response of the Honeycomb Metal Substrate Catalytic Converter with Coating aligns with the intermittent operation of hybrid vehicles, ensuring consistent emission control.

The Honeycomb Metal Substrate Catalytic Converter with Coating sets a benchmark for emission control solutions, merging material science with environmental engineering. As global emission norms tighten, its adaptability across automotive and industrial sectors will continue to drive sustainable advancements in air quality management.