To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-06-20

Under the dual pressure of global carbon emission reduction and pollution prevention, environmental protection material innovation is undergoing a revolutionary breakthrough. With its unique structural advantages and material properties, metal honeycomb substrate has become a key technology carrier in the field of motor vehicle exhaust treatment and industrial waste gas treatment. The following content is based on the latest engineering practice and scientific research results, and will systematically analyze the scene application of metal honeycomb substrate in the two core environmental protection industries, so that everyone can better understand metal honeycomb substrate.

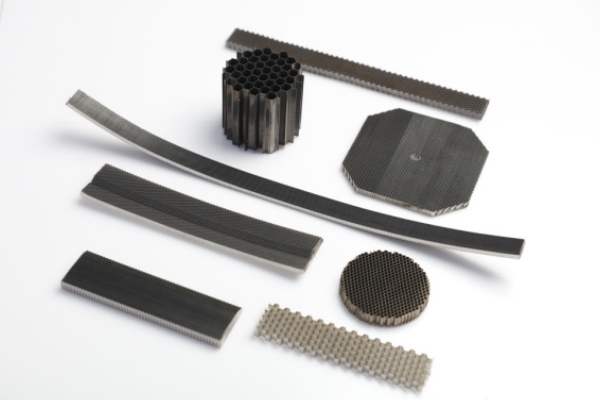

Metal honeycomb substrate uses iron-chromium-aluminum or titanium alloy foil, and forms a honeycomb structure through a special welding process. It has three core advantages:

Fluid dynamics optimization: The sinusoidal waveform channel design makes the airflow distribution uniformity reach more than 95% (traditional ceramic carriers are only 82%).

Heat conduction enhancement: The thermal conductivity of metal materials reaches 16W/(m·K), which is 8 times higher than that of ceramic carriers, and the catalyst ignition time is shortened by 40%.

Mechanical strength breakthrough: Thermal shock resistance exceeds 1,000 hot and cold cycles .

Diesel vehicle emission reduction upgrade

Under the National VI standard, the new metal carrier SCR system achieves NOx conversion efficiency ≥98.5% and PM capture efficiency 99%. Anti-sulfur poisoning coating technology extends the catalyst life to 800,000 kilometers (compared with 500,000 kilometers for ceramic carriers).

Technical iteration of gasoline vehicles

The three-way catalytic converter adopts a gradient channel design, and CO emissions are reduced by 63% during the cold start phase (NEDC working condition test). Ultra-thin substrates (0.04mm wall thickness) for motorcycles achieve a 35% volume reduction and meet Euro 5 emission standards.

VOCs treatment

The heat recovery efficiency of metal thermal storage bodies in RTO equipment reaches 97%, and the operating energy consumption is reduced by 28%. The petrochemical industry uses platinum-palladium bimetallic coatings, and the degradation rate of benzene series is increased to 92% (200℃ working conditions).

Chemical tail gas purification

The square staggered channel structure makes the NH3-SCR denitrification efficiency exceed 96% (actual data from cement plants), and the anti-carbon deposition coating technology solves the problem of high-temperature tar adhesion in the coking industry.

As a new generation of solutions in the field of environmental protection, metal honeycomb substrate is showing its cross-domain transformation potential. From motor vehicle exhaust purification to industrial VOCs treatment, this technology has achieved the simultaneous optimization of treatment efficiency and energy consumption through the dual breakthroughs of material innovation and structural optimization.