To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-29

In many enclosure projects, ventilation and EMI shielding are treated as two separate tasks.

Thermal issues are addressed first. EMI problems come later, usually during compliance testing. By that point, the enclosure layout is already fixed, and any change becomes costly.

This article looks at ventilation from a different angle. Instead of asking how much air is needed, it focuses on what happens to shielding once an opening is introduced, and how a Planar Waveguide Vent fits into that decision.

Ventilation with EMI Shielding Kept Intact

In industrial control cabinets, ventilation is rarely optional.

Power modules, drives, and control electronics all generate heat. Once power density goes up, airflow becomes part of the design whether you want it or not.

The problem usually starts at the vent.

Where EMI Issues Begin

Most cabinets still rely on simple punched holes or louver panels for airflow. From a thermal standpoint, this is fine. From an EMI standpoint, it often creates problems that only show up during testing.

A metal enclosure works as a shield because its surface is continuous. Once that surface is broken into large or repeated openings, the enclosure no longer behaves the same way at higher frequencies.

In practice, EMI failures often appear after thermal improvements are added, not before.

Treating the Vent as Part of the Shield

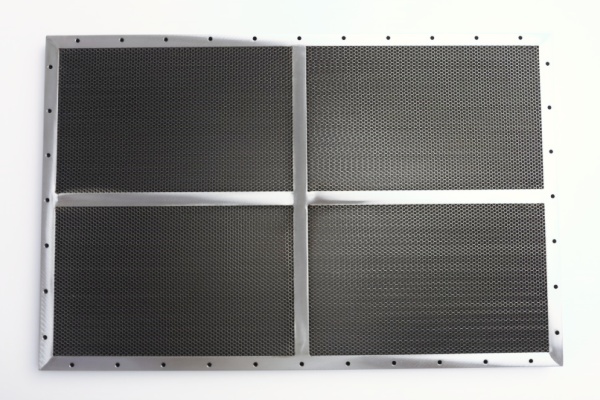

A Planar Waveguide Vent approaches the opening differently.

Instead of treating ventilation as a necessary weakness, the vent is designed as a controlled path. Air moves through the structure, but electromagnetic energy does not pass as easily.

There is no coating doing the work, and no additional absorbing layer. The shielding effect comes from geometry.

From an enclosure perspective, the vent becomes part of the shielding surface rather than a break in it.

How It’s Used in Control Cabinets

In automation systems and industrial enclosures, these vents are typically installed:

At intake or exhaust locations close to heat sources

On cabinet doors or side panels where space is limited

In systems that already struggle to balance thermal and EMC requirements

Because shielding performance depends on structure rather than airflow speed, changes in fan selection or operating conditions have less impact on EMI behavior.

Why This Matters During Design

This approach shifts EMI control earlier in the design process.

Instead of adding fixes after testing, shielding continuity is maintained at the mechanical layout stage. Thermal and EMC considerations stop working against each other.

For control cabinets that must meet both temperature limits and EMI standards, a Planar Waveguide Vent is not a workaround. It is simply a cleaner way to define the ventilation opening.

In electronic enclosures and control cabinets, the ventilation opening is often the weakest point in the shielding design.

A Planar Waveguide Vent does not eliminate the need for airflow, nor does it attempt to compensate for poor layout elsewhere. What it does is keep the vent from becoming an uncontrolled leak.

When shielding continuity is considered at the same time as thermal requirements, fewer compromises are needed later. In many cases, that alone is reason enough to treat the vent as a functional part of the enclosure, not just a hole for air to pass through.