To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-19

Communication equipment rooms usually have one common problem: heat needs to get out, but EMI needs to stay in. Ventilation openings solve the first issue and often create the second.

In many cases, EMI problems in these rooms are not caused by the equipment itself, but by openings made for airflow.

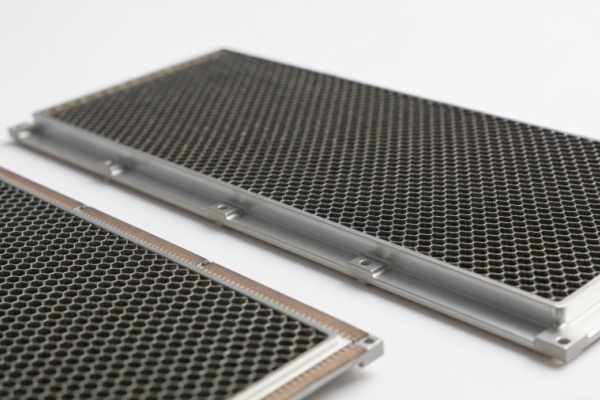

Planar wave shielded ventilation panels are often used at these openings.

In communication rooms, these panels are mostly installed on rack cabinets. Common positions include cabinet doors, rear panels, and sometimes side panels close to fan units.

Another place is partition walls between equipment zones. When rooms are divided into functional areas, airflow is still needed, and shielded vents are added to the partitions.

The exact position matters. Panels placed close to RF modules or high-frequency cables tend to be more sensitive to mounting quality.

Cooling is normally handled by forced air. Fans push air through the cabinet, and the ventilation panel sits directly in the flow path.

If the airflow entering the panel is uneven, pressure builds up in certain areas. This does not always show up in EMI tests, but it affects long-term stability. Panels may slowly deform, especially larger ones.

In real installations, airflow is often checked again after the panel is mounted, not just during design.

Shielding effectiveness data usually comes from lab tests. Communication rooms are different.

Cabinet frames are not always perfectly flat. Paint, surface treatment, or slight deformation can reduce electrical contact. Even when the panel itself is fine, poor contact at the edges can lower shielding performance.

Because of this, conductive gaskets or dedicated grounding points are commonly added around the panel frame.

Some issues show up repeatedly in communication rooms:

Panel not seated flat in the frame

Uneven tightening of fasteners

Poor grounding between panel and cabinet

Gaps caused by paint or surface coating

None of these are design problems, but they affect performance.

Communication equipment rooms run continuously. Fans vibrate. Cabinets heat up and cool down. Panels don’t move much, but over time things change.

Periodic checks are usually simple: look for loose fasteners, check grounding continuity, and inspect for visible deformation. These checks often prevent later EMI issues.

When planar wave shielded ventilation panel are used in communication equipment rooms, they are rarely standalone components. Their performance depends on how they are mounted and how the surrounding structure is built.

Most issues are not found during initial testing, but after the system has been running for a while.