To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-17

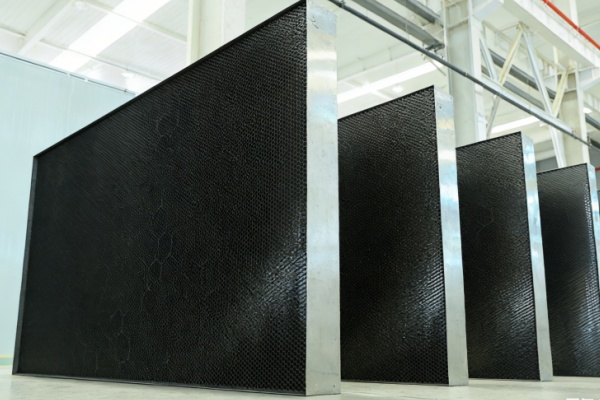

Honeycomb straighteners are often specified as simple flow-conditioning components. Once the cell size and thickness are defined, they are assumed to behave predictably. In practice, performance differences between batches are one of the most common issues users encounter.

These differences rarely come from design changes. They come from inconsistency during production.

A honeycomb straightener works by breaking large-scale flow structures into smaller, more uniform channels. For this to happen reliably, each cell needs to behave in roughly the same way. When cell geometry varies, the straightener no longer conditions the flow evenly.

Small dimensional changes are easy to overlook. Slight variation in cell width, wall thickness, or straightness does not stand out during visual inspection. However, when air or gas passes through hundreds or thousands of cells, these differences accumulate. Some channels accelerate the flow, others slow it down, and the result is uneven velocity distribution downstream.

Length-to-diameter ratio is another area where consistency matters. A few cells that are shorter than intended may not straighten the flow effectively, while longer cells increase pressure drop. When these variations appear across a single panel, the straightener starts behaving less like a uniform flow conditioner and more like a collection of mismatched elements.

Bonding and assembly also play a role. Inconsistent bonding can partially block cells or deform walls. These defects are often local, but their impact spreads downstream. Flow separation or localized turbulence introduced at one point does not stay confined to that area.

Material behavior adds another layer. Differences in material stiffness or residual stress can cause slight deformation during handling or installation. A honeycomb straightener that looks flat on the bench may distort once clamped into a duct or test section, changing effective cell alignment.

Surface condition affects pressure loss as well. Variations in surface roughness or contamination increase resistance unevenly. Even when average pressure drop remains within specification, local differences can reduce flow uniformity.

These issues are difficult to correct after production. Once a honeycomb straightener is installed, performance problems are often blamed on upstream flow conditions or measurement error. The underlying cause may simply be that the straightener does not behave uniformly across its area.

Consistent production does not mean holding extreme tolerances everywhere. It means controlling the parameters that directly influence flow behavior and ensuring they remain stable from batch to batch.

In applications where flow uniformity matters—such as wind tunnels, measurement sections, or sensitive cooling systems—consistency in honeycomb straightener production is not a refinement. It is a requirement for predictable performance.

When consistency is built into the manufacturing process, honeycomb straightener tend to behave as expected. When it is not, even a well-designed straightener can produce results that are difficult to explain or reproduce.