To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-09

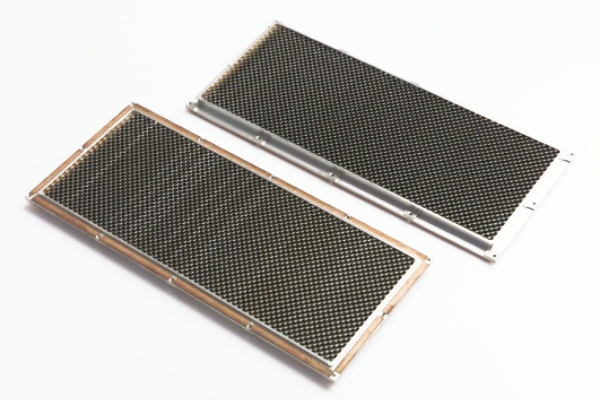

Shielded Ventilation Window vs Standard Vent Panel. A Practical Comparison from MAT Aviation Manufacturing Co., Ltd.

At MAT Aviation Manufacturing Co., Ltd., ventilation solutions are evaluated based on system requirements, not appearance.Both shielded ventilation windows and standard vent panels move air.The difference lies in electromagnetic control.

Functional purpose

A standard vent panel is designed for airflow only.

It supports cooling.

A shielded ventilation window is designed to support airflow while maintaining shielding continuity.

It is part of an EMI control system.

In environments without electromagnetic sensitivity, this distinction may not matter.

In controlled systems, it does.

Structural differences

Standard vent panels typically use perforated metal or open mesh.

Hole size is selected for airflow efficiency.

A shielded ventilation window uses waveguide structures.

Channel geometry is calculated to block electromagnetic propagation while allowing air to pass.

This difference determines performance limits.

Shielding capability

Standard vent panels provide little shielding.

They often become leakage points in enclosed systems.

An electromagnetic shielding ventilation window is designed to meet defined attenuation levels across specific frequency ranges.

Performance depends on material conductivity, waveguide geometry, and assembly quality.

Without proper design, ventilation compromises shielding integrity.

Installation and grounding

Standard vent panels require minimal installation effort.

Electrical bonding is usually not required.

Shielded ventilation windows must be electrically bonded to the enclosure.

Contact surfaces must remain conductive.

Gaps reduce effectiveness.

Installation quality has a direct impact on performance.

Impact on system reliability

In communication equipment, aerospace systems, and high-power electronics, EMI affects stability.

Noise can propagate through ventilation openings.

Using standard vent panels in these environments often leads to interference issues or failed compliance tests.

Shielded ventilation windows reduce these risks when properly specified and installed.

Maintenance considerations

Standard vent panels are simple to maintain.

However, they offer no EMI protection.

Shielded ventilation windows require inspection over time.

Corrosion, deformation, or contamination can reduce shielding performance.

Maintenance preserves long-term reliability.

Selection based on application

At MAT, selection is based on operating conditions.

Standard vent panels are suitable when:

EMI is not a concern

Systems are non-sensitive

Cooling is the only requirement

Shielded ventilation windows are required when:

Shielding continuity must be maintained

EMC compliance is mandatory

System stability depends on EMI control

A shielded ventilation window is not a universal replacement.

It is an application-driven solution.

Engineering perspective

Ventilation openings often define the weakest point in a shielded enclosure.

Ignoring this leads to design compromises.

A properly selected shielded ventilation window addresses airflow and shielding simultaneously.

From an engineering perspective, this is a preventive measure, not an upgrade.