To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-08

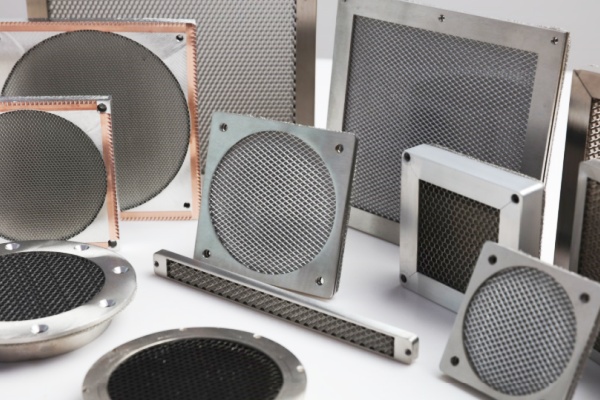

At MAT Aviation Manufacturing Co., Ltd., production of a shielded ventilation window starts with material control. Performance depends on the first step.

All incoming materials are inspected before entering our production line.

Metal sheets, waveguide cores, frame materials.

We check:

Thickness consistency

Surface flatness

Electrical conductivity

Oxidation and contamination

Materials that do not meet requirements are separated immediately.

They are not mixed into production.

Each batch is recorded for traceability.

Approved materials are cut according to engineering drawings.

Dimensional tolerance is controlled at this stage.

Edges are deburred.

Sharp corners removed.

Surfaces cleaned to eliminate oil and dust.

We do not skip this step.

Poor preparation leads to assembly and performance issues later.

The waveguide core defines the shielding behavior of the product.

Channel size, length, and spacing determine attenuation performance.

At MAT, waveguide structures are formed using dedicated tooling.

Consistency across the entire panel is required.

After forming, each core is checked for:

Deformation

Blocked channels

Uneven geometry

Cores that fail inspection are rejected before assembly.

Frames provide mechanical strength and electrical continuity.

Flatness is critical.

Depending on design, frames are machined or stamped.

Contact surfaces are kept free of insulating coatings.

Before assembly, we verify the fit between frame and waveguide core.

Any mismatch increases the risk of EMI leakage.

Assembly is carried out under controlled conditions.

Waveguide cores are aligned with frames manually and visually.

Fasteners are applied using specified torque values.

Over-tightening causes distortion.

Under-tightening creates gaps.

During assembly, our operators verify:

Core alignment

Frame contact quality

Mechanical stability

Units that do not meet requirements are corrected or removed from the line.

Some shielded ventilation windows require surface treatment for corrosion resistance.

This process is controlled carefully.

Coating thickness is monitored.

Excess coating reduces conductivity.

Insufficient coating affects durability.

Electrical contact areas remain conductive.

Finished products undergo inspection before release.

We perform:

Dimensional measurement

Visual inspection

Electrical continuity checks

Shielding effectiveness testing is conducted based on project or customer requirements.

Only qualified electromagnetic shielding ventilation windows proceed to packaging.

Products are cleaned before packaging.

Protective materials are used to prevent deformation during transport.

Batch numbers link finished products back to raw material records.

This allows us to trace and respond quickly if issues arise after installation.

At MAT Aviation Manufacturing Co., Ltd., every step from raw material to finished product affects performance.

This process control is how we maintain consistency in shielded ventilation window production.