To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-07

Communication equipment rooms generate heat.

Racks run continuously. Power density is high. Cooling is not optional.

At the same time, these rooms are sensitive to electromagnetic interference.

Base stations, servers, switching systems, control units.

Signal stability matters.

This is where the electromagnetic shielding ventilation window becomes necessary.

Equipment rooms usually require air intake and exhaust openings.

Once an opening is created, shielding continuity is broken.

Without proper treatment, ventilation holes allow EMI leakage.

External interference enters.

Internal noise escapes.

In communication systems, this can lead to:

Signal instability

Increased error rates

Interference between adjacent equipment

Compliance issues during EMC testing

Standard ventilation panels are not enough in these environments.

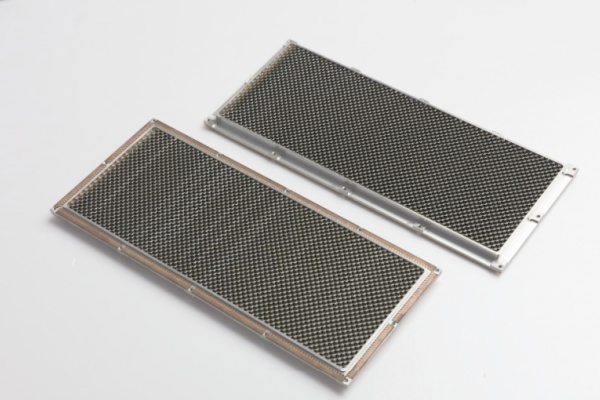

An electromagnetic shielding ventilation window allows airflow while maintaining shielding performance.

The core principle is simple.

Air passes through.

Electromagnetic waves do not.

This is achieved through waveguide structures, controlled aperture size, and conductive materials.

When designed correctly, the ventilation window becomes part of the shielding system rather than a weak spot.

Shielded ventilation windows are commonly used in:

Equipment room walls

Shielded cabinets and enclosures

Air inlet and outlet panels

Cooling paths between isolated zones

In high-density rooms, multiple ventilation windows may be installed to balance airflow and attenuation.

Placement matters.

So does orientation.

Improper positioning can reduce effectiveness even if the product itself meets specifications.

Communication equipment rooms operate continuously.

This affects how ventilation windows are selected.

Key factors include:

Required shielding effectiveness across target frequency ranges

Airflow volume and pressure drop

Structural strength for long-term operation

Resistance to corrosion and dust

An electromagnetic shielding ventilation window designed for light industrial use may not be suitable for communication rooms.

Design must match the actual operating environment.

Performance loss often comes from installation, not product design.

Common issues include:

Gaps between the ventilation window and mounting surface

Poor electrical contact

Inconsistent fastening torque

Paint or coating interfering with conductivity

In communication equipment rooms, grounding continuity is critical.

Ventilation windows must be electrically bonded to surrounding structures.

This step is often overlooked during on-site installation.

Communication rooms are not static environments.

Temperature changes.

Humidity fluctuates.

Dust accumulates.

Over time, shielding performance can degrade if ventilation windows are not inspected.

Routine checks usually focus on:

Mechanical deformation

Surface corrosion

Loosened fasteners

Blocked airflow channels

A damaged or contaminated ventilation window can affect both cooling and EMI control.

When properly selected and installed, an electromagnetic shielding ventilation window supports system stability.

Cooling remains effective.

Shielding integrity is preserved.

Interference risks are reduced.

For communication equipment rooms, this is not an accessory component.

It is part of the overall EMC strategy.

Ignoring ventilation shielding often leads to problems later.

Addressing it during design and installation avoids costly rework.