To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-10-14

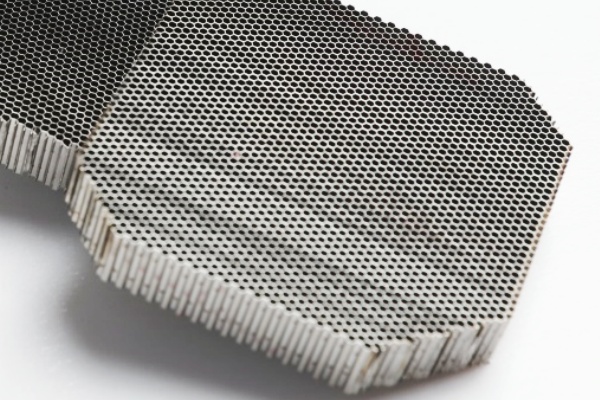

If you’ve ever worked around a laser cutting setup, you’ve probably noticed that most machines sit on a honeycomb-style platform. There’s a good reason for that. The Laser cutting machines honeycomb base isn’t just there for support — it plays a key role in how clean and accurate the cuts turn out.

The idea is pretty simple. The honeycomb structure gives strong, even support without being heavy. Each small cell helps spread out the load so the material stays flat while cutting. Because of that, the work surface doesn’t warp easily, and thin sheets like acrylic or stainless steel stay steady during the process. Over time, you’ll find that a Laser cutting machines honeycomb table keeps its shape far better than a solid plate would.

Another big reason people use honeycomb tables is to deal with laser reflection. When the beam cuts through the workpiece, some of that energy bounces back. If it hits the bottom of your material again, it can leave burn marks or rough spots. The open-cell design of the Laser cutting machines honeycomb platform lets that extra light pass through instead of reflecting it back, which helps keep the cut clean and smooth.

Ventilation is another plus. Because the platform isn’t solid, air and smoke can move through it easily. That helps with cooling and keeps fumes from collecting under the material — both of which make a difference when you’re cutting for long periods.

So, compared with a solid metal table, the Laser cutting machines honeycomb base gives better airflow, less reflection, and more stability. It’s one of those simple engineering choices that makes a big difference in everyday cutting work — practical, efficient, and built for precision.