To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-19

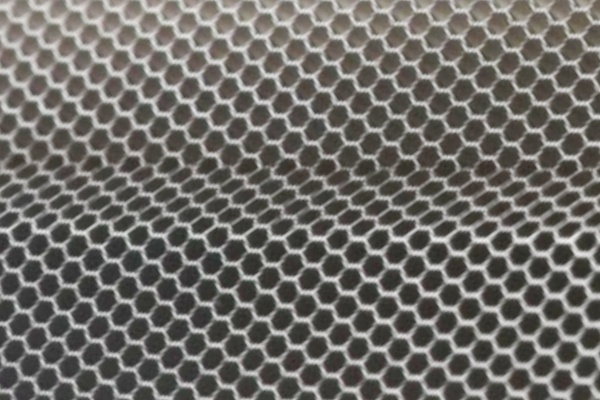

Anyone who has spent time with a laser cutter knows the platform isn’t just there to hold the sheet in place. The Laser cutting machines honeycomb actually changes how the machine performs, from how clean the cut looks to how long the equipment lasts.

One big advantage is reflection control. On a solid table, the laser has nowhere to go once it burns through. That leftover energy bounces back, and sometimes it hits the underside of the material or, worse, the machine optics. With a Laser cutting machines honeycomb platform, the beam drops straight through the cells instead of reflecting back. That means the laser energy is used where it should be—on the cut—and not wasted or causing damage.

Safety is another reason this design matters. Stray reflections aren’t just inefficient, they can also be a hazard. By letting the beam pass through cleanly, the Laser cutting machines honeycomb keeps the working area safer and more predictable. It’s one of those things you don’t notice until you’ve run jobs without it—and then you see the difference right away.

There’s also the question of machine life. Constant reflections and heat buildup take a toll on optics and internal parts. Over time, that means more maintenance and shorter service intervals. Using a Laser cutting machines honeycomb platform helps cut down on that wear and keeps the machine running smoothly for longer.

At the end of the day, the honeycomb isn’t just a support surface—it’s part of the cutting process itself. It saves energy, improves safety, and extends the life of the machine. Once you get used to running with a Laser cutting machines honeycomb, it’s hard to imagine going back to anything else.