To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-18

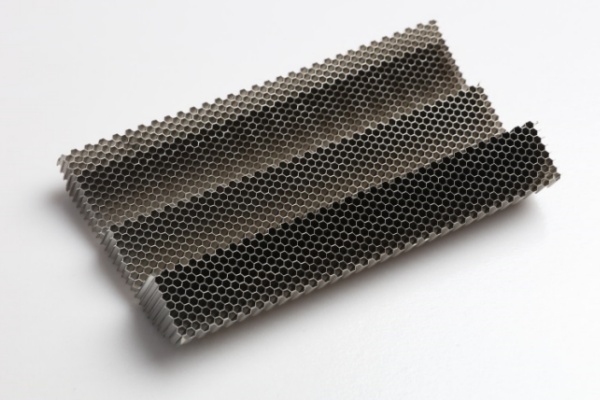

Anyone who spends time around a laser cutter knows the platform makes a big difference. The Laser cutting machines honeycomb table is one of those tools you don’t think much about at first, but once you start switching between materials, you realize how much it matters.

Take metal sheets, for example

On a flat solid table, sparks and molten bits have nowhere to go, and before you know it, you’ve got burn marks or even reflections hitting the underside. With a Laser cutting machines honeycomb table, all that debris just falls away, leaving the sheet supported but clean. It also keeps thin metal from bending or warping because the whole surface stays flat.

Wood is another story

It loves to scorch if the smoke gets trapped under it. The honeycomb grid gives that smoke somewhere to escape, which cuts down on burn marks and keeps the edges looking sharp instead of blackened. It also keeps the heat from building up, which can save delicate pieces from warping.

Acrylic is even more sensitive

Without a good platform, you end up with hazy bottoms and rough edges. The open design of the Laser cutting machines honeycomb table reduces reflections and lets you dial in settings that leave edges smooth and clear. Anyone who has tried to get that “polished” edge knows the table makes all the difference.

Fabrics and other light materials have their own challenges

They shift around if they’re not supported well. A fine-cell Laser cutting machines honeycomb holds them steady without scorching, making clean cuts possible even with tricky textiles.

The trick is matching the honeycomb to the job

Coarse grids are better for rigid sheets; finer grids give lightweight or flexible materials the stability they need. Once you start pairing the right setup with the right material, you’ll notice the cuts are cleaner, faster, and you spend less time fixing mistakes.

At the end of the day, the Laser cutting machines honeycomb isn’t just a table—it’s part of the cutting process itself. Knowing how to use it with different materials can be the difference between an okay result and a professional-looking finish.