To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-09

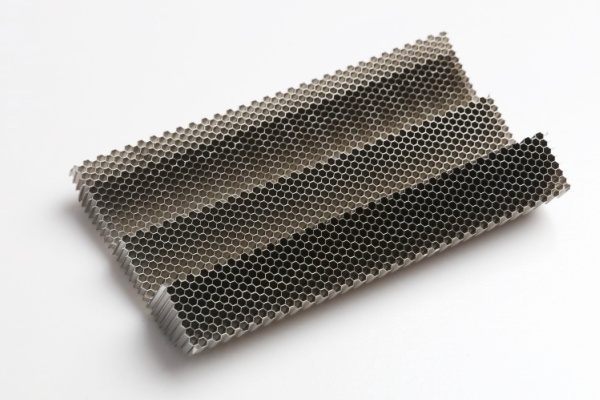

If you work in aerospace or defense, you know that every component has to withstand some of the toughest conditions out there. Think of the searing heat inside a jet engine, the violent shaking during a missile launch, or the years of non-stop operation required from critical systems. It’s in places like these that metal substrate shine. Their unique honeycomb design and metal construction give them a rugged durability that’s hard to beat.

Heat is a major destroyer of performance. In propulsion and exhaust systems, temperatures can swing dramatically in seconds. While many materials warp or break down under these conditions, metal catalyst substrates are made to take the heat. The special alloys used can handle thermal shock without cracking, meaning they keep doing their job—supporting the catalyst and promoting chemical reactions—even when things get extremely hot.

Then there’s vibration. Whether it’s a drone flying through turbulence or a ground vehicle moving over rough terrain, shaking is a constant threat. The honeycomb structure of metal substrate isn’t just strong—it’s also flexible. It absorbs impacts and vibrations that would shatter more brittle materials. That resilience is a big reason why these substrates are trusted in applications where maintenance isn’t possible, and failure is not an option.

Long life is another advantage. In remote or hard-to-reach systems, you need components that last. Metal catalyst substrates resist wear, corrosion, and thermal fatigue far better than many alternatives. That means fewer replacements, less downtime, and better cost efficiency over time—a crucial benefit for long-term missions or equipment stationed in isolated locations.

What really makes the honeycomb structure valuable is how it balances performance with practicality. The design offers plenty of surface area for catalytic reactions, but it’s also efficient on space and weight. For aircraft and spacecraft, where every gram matters, that’s a major advantage.

It’s not hard to see why aerospace and defense engineers so often turn to metal catalyst substrates. They stand up to heat, shrug off vibration, and keep working year after year. In industries where reliability is everything, that’s exactly what’s needed.