To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-02

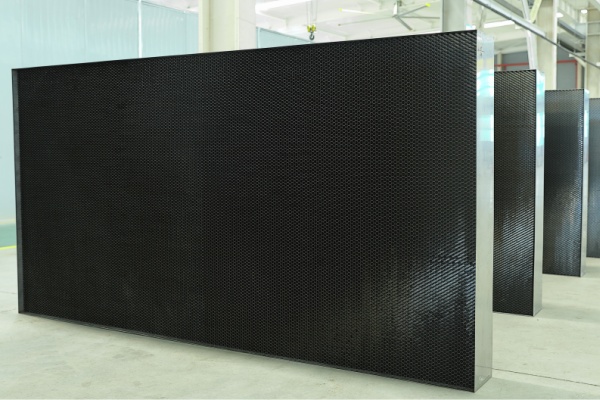

Wind Tunnel Revelations

In controlled wind tunnel tests comparing 1.5mm-thick perforated panels with honeycomb waveguide ventilation boards of equivalent porosity, the results were striking. While traditional panels created turbulent eddies (increasing pressure drop by 12-15% at 10m/s airflow), the honeycomb structure guided air molecules through parallel channels, reducing drag by approximately 22%. Maintenance teams at semiconductor cleanrooms reported an added benefit: the honeycomb waveguide ventilation board's directional airflow minimized particulate deposition on sensitive equipment.

The Physics of Quiet

Acoustic testing revealed even more dramatic contrasts. When subjected to 500-2000Hz noise frequencies—the typical range for industrial fan systems—perforated panels attenuated sound by merely 3-5dB. The honeycomb waveguide ventilation board, however, achieved 8-11dB reduction through its unique dual-stage damping: first by breaking sound waves into smaller coherent packets within the hexagonal cells, then by forcing phase cancellation through staggered depth variations. Automotive HVAC manufacturers have since adopted this design to eliminate cabin "wind whistling" complaints.

Beyond Laboratory Data

Field applications further validate the superiority. At a Guangzhou data center, replacing legacy perforated panels with honeycomb waveguide ventilation boards reduced server cooling Energy consumption by 18% annually. The boards' structural rigidity (withstanding 2.3kPa loads without deformation) also eliminated the "drumming effect"—a common vibration issue with thin perforated metals during typhoon seasons.

The Future Is Hexagonal

As sustainability regulations tighten globally, the honeycomb waveguide ventilation board's material efficiency becomes decisive. Its 40% weight reduction versus solid baffles translates to lower shipping emissions, while the aluminum alloy version achieves 92% recyclability. Perhaps most tellingly, three major airport retrofit projects recently specified these boards not just for performance, but because their mathematical beauty made engineers smile—a rare feat in utilitarian industrial design.