To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-01

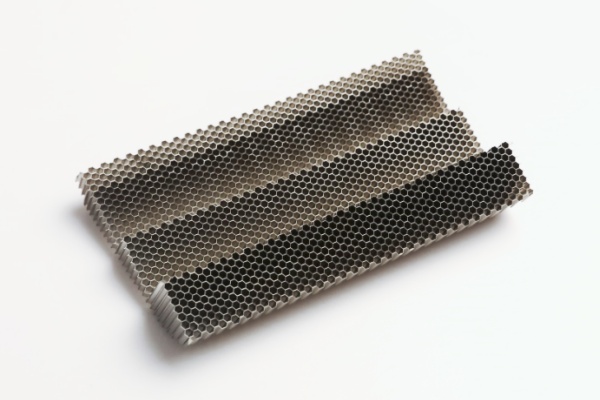

I remember my first visit to the manufacturing plant where they make these incredible metal substrate. The air carried the distinct scent of hot metal and machinery oil as I watched workers transform simple rolls of alloy into sophisticated honeycomb structures. What struck me most was how this process blended modern technology with traditional craftsmanship.

The journey begins with selecting the right materials. I watched as technicians examined rolls of specialized alloy, feeling the texture between their gloved fingers. "This iron-chromium-aluminum blend," one engineer explained, "can handle temperatures that would make ordinary metals warp and fail." They measure the foil thickness with laser precision, knowing that even a micron's variation could affect the final product's performance.

The corrugation process fascinated me. Massive machines press perfect wave patterns into the flat metal sheets. I noticed experienced operators listening to the machinery—they could tell by sound when something wasn't quite right. "Each wave pattern," a technician told me, "is designed to create maximum surface area while maintaining strength. It's like engineering origami at microscopic levels."

Assembly requires incredible patience and skill. Workers layer the flat and corrugated sheets, building up the honeycomb pattern that makes these substrates so effective. I watched one woman who'd been doing this for twenty years—her hands moved with unconscious precision, aligning layers that would soon be permanently bonded together. "You develop a feel for it," she said without looking up from her work. "Your eyes and hands learn to spot problems before they become defects."

The bonding process still seems like magic to me. The layered metal enters massive ovens where temperatures are carefully controlled to fuse the layers without compromising the material's integrity. The thermal engineer showed me how they adjust the heating patterns based on the day's humidity and temperature. "We've learned that atmosphere affects the bond quality," he explained. "What works in winter doesn't always work in summer."

Coating application is where science meets art. Technicians apply specialized coatings while constantly monitoring environmental conditions. I saw them adjusting formulas in real-time based on humidity readings. "Too dry, and the coating cracks," the lead chemist told me. "Too humid, and it doesn't adhere properly. We're always balancing conditions."

The final thermal treatment activates the coatings in massive curing ovens. Through observation windows, I saw the transformation occur—the moment the substrate becomes functionally complete. Quality control technicians take samples every hour, running tests that simulate years of use in just days.

What continues to amaze me is how much human expertise complements the automated processes. I met quality inspectors who could identify issues by sound alone—the slight change in machinery hum that indicates a problem. Their knowledge, built over decades, catches things machines might miss.

The evolution of these manufacturing processes shows our constant drive for improvement. Where we once measured success in millimeters, we now work in micrometers. The latest substrates have channel patterns so precise they look like metal lacework under magnification—all while maintaining structural strength.

These advances matter because the substrates face incredible challenges in real-world use. They must withstand temperature swings from freezing cold to red-hot, constant vibration, and chemical exposure—all while maintaining performance. The manufacturing process prepares them for these challenges through rigorous testing and quality control.

Seeing the finished substrates ready for shipment, I understood why this combination of human skill and technological precision creates products that meet increasingly demanding specifications. Each honeycomb structure represents countless hours of refinement and dedication to quality—a commitment that continues driving innovation in manufacturing technology.