To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-13

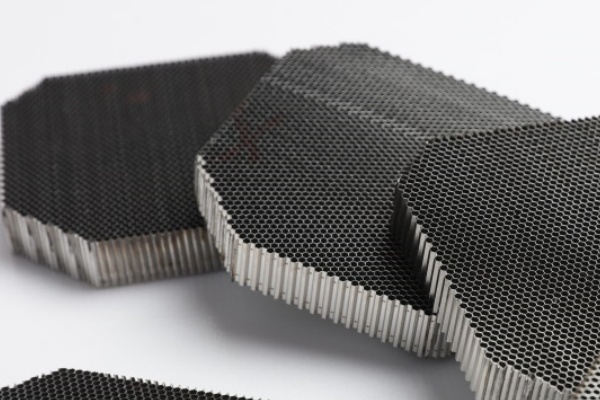

Electromagnetic interference (EMI) threatens sensitive electronics, while inadequate ventilation risks thermal failure. Selecting the right EMI shielding ventilation board is critical. Among solutions like wire mesh or perforated panels, honeycomb structures deliver unmatched performance. Here’s why honeycomb technology dominates high-stakes applications.

Honeycomb EMI shielding ventilation boards leverage the waveguide beyond-cutoff principle. Each hexagonal cell acts as a miniature waveguide tube:

Electromagnetic waves below the cutoff frequency (determined by cell diameter) decay rapidly within the cell depth.

Smaller cells = higher cutoff frequencies, enabling GHz-range blocking.

Result: Consistent 80–120 dB SE across broad frequency bands (MHz–40 GHz).

Alternative Limitations:

Wire Mesh: Gaps between strands create leakage paths. SE drops sharply above 1 GHz.

Perforated Panels: Large holes behave like slot antennas, radiating high-frequency EMI.

Honeycomb design achieves an industry-leading open area ratio (70–85%) with minimal turbulence:

Straight parallel channels enable laminar airflow.

Low pressure drop reduces cooling system load.

Alternative Limitations:

Wire Mesh: Knitted wires disrupt airflow, increasing pressure drop.

Perforated Panels: High open area possible, but requires added shielding screens that restrict flow.

Monolithic metal honeycomb cores (aluminum/steel) provide:

Vibration/shock resistance critical for aerospace or mobile systems.

Panel reinforcement – strengthens cabinet walls.

Corrosion resistance via optional plating.

Alternative Limitations:

Wire Mesh: Prone to snagging, tearing, and compression damage.

Perforated Panels + Screens: Screens dent easily; dissimilar metals risk galvanic corrosion.

Honeycomb EMI shielding ventilation boards excel in harsh conditions:

Seamless gasket integration achieves IP54+ ratings.

Withstands temperature extremes (-55°C to +125°C).

Resists humidity, dust, and chemical exposure.

Alternative Limitations:

Conductive Foam: Degrades under UV/heat; low airflow capacity.

Wire Mesh: Traps contaminants; hard to clean.

When failure is not an option – military comms, medical imaging, 5G infrastructure, or industrial automation – honeycomb EMI shielding ventilation boards are the proven choice. They solve the core paradox:

Highest SE at high frequencies where alternatives fail.

Maximized airflow without SE compromise.

Zero maintenance versus fragile screens or foams.

While wire mesh and perforated panels suit cost-sensitive, low-frequency needs, honeycomb technology sets the standard for demanding EMI and thermal environments. Its engineered balance of physics-based shielding, optimized ventilation, and rugged durability makes it the ultimate EMI shielding ventilation board solution. For cabinets protecting mission-critical electronics, honeycomb isn’t just an option – it’s insurance.