To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-11

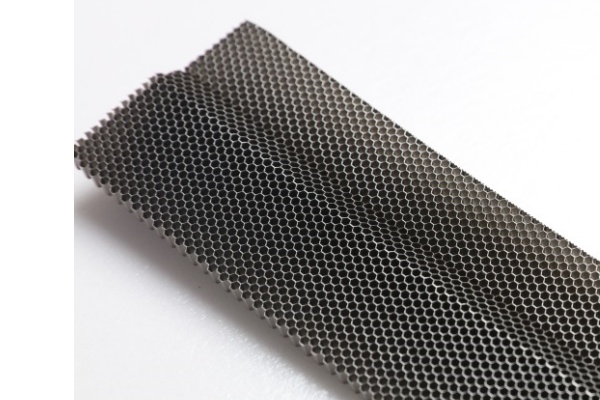

Every electronics enclosure faces a fundamental conflict: blocking disruptive electromagnetic interference (EMI) while allowing essential airflow for cooling. The cabinet electromagnetic shielding ventilation board resolves this paradox. Among competing technologies, honeycomb structures stand apart. Let’s explore how they work and why they dominate demanding applications.

Solid metal blocks EMI but suffocates equipment. Simple holes or mesh allow airflow but leak energy like antennas. The solution lies in structures that exploit the physics of electromagnetic waves – specifically, the waveguide beyond cutoff principle.

Honeycomb cabinet electromagnetic shielding ventilation boards consist of thousands of tightly packed, small-diameter hexagonal metal tubes (cells) bonded together. Their power comes from physics:

Waveguide Cutoff Principle: Each cell acts as a waveguide. Electromagnetic waves below a specific cutoff frequency (determined by the cell’s diameter) cannot propagate through the tube. They decay exponentially within a short distance.

Frequency Control: Smaller cell diameters = higher cutoff frequencies. By designing cells smaller than the wavelength of the target interference, high-frequency EMI is effectively blocked.

Airflow Paths: Air passes freely along the straight, parallel channels with minimal turbulence or restriction.

Superior Shielding Effectiveness (SE): Achieves consistently high SE (often 80-120 dB+) across a wide frequency range (MHz to GHz), outperforming most alternatives.

Optimal Airflow-to-Shielding Ratio: Offers the best balance, providing significant open area (typically 70-85%) for cooling while maintaining excellent EMI containment.

Robustness & Durability: The monolithic metal structure (usually aluminum or steel) resists physical damage, vibration, and corrosion. It maintains shielding integrity over time.

Low Pressure Drop: Straight hexagonal channels minimize airflow resistance, reducing the burden on cooling systems.

Environmental Sealing: Easily integrated with gaskets to provide high IP ratings (dust/water ingress protection) alongside EMI shielding.

Structural Rigidity: Adds significant strength to cabinet panels.

Customizability: Cell size, depth, material, and plating can be tailored to specific SE, airflow, and environmental needs.

While honeycomb excels, other cabinet electromagnetic shielding ventilation board types exist:

Metal Mesh (Knitted Wire):

Pros: Lower cost, flexible, lightweight.

Cons: Lower SE (especially at higher frequencies), susceptible to snagging/tearing, higher pressure drop than honeycomb, less robust.

Perforated Plate + Shielding Screen:

Pros: Very high open area possible, lower cost for large holes.

Cons: Poor high-frequency shielding (large holes act as slot antennas), screen vulnerable to damage, potential for galvanic corrosion.

Conductive Foam/Gasket:

Pros: Excellent for sealing irregular gaps/joints.

Cons: Very low open area, not a primary ventilation solution; high compression force needed, degrades over time.

Choosing depends on critical factors:

Frequency Spectrum: What EMI frequencies must be blocked? Honeycomb is essential for GHz+ shielding.

Required Shielding Level (SE): How much attenuation (dB) is needed? Honeycomb delivers the highest, most reliable SE.

Airflow Demand (CFM): How much cooling is critical? Honeycomb offers the best open area without sacrificing SE.

Environmental Factors: Exposure to dust, moisture, chemicals, vibration, or physical impact? Honeycomb provides superior resilience and sealing potential.

Space/Weight Constraints: Honeycomb adds strength but has weight.

When performance, reliability, and longevity are non-negotiable, honeycomb cabinet electromagnetic shielding ventilation board are the definitive choice. Their unique exploitation of waveguide physics delivers unmatched simultaneous EMI suppression and cooling airflow. While alternatives suit less demanding applications, honeycomb technology remains the benchmark for critical infrastructure, military systems, sensitive medical equipment, high-power telecom, and advanced industrial controls. Its blend of shielding excellence, ventilation efficiency, and robust construction makes it the core component for truly secure and reliable electronic enclosures.