To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-08

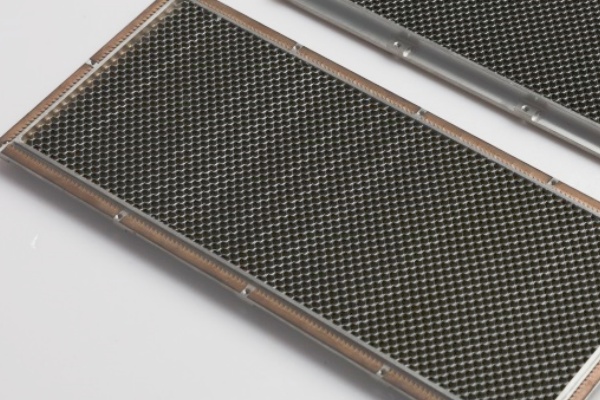

From silencing roaring data centers to protecting sensitive medical equipment, Honeycomb Waveguide Ventilation Boards are solving previously unsolvable engineering challenges. This advanced technology enables unprecedented harmony between ventilation efficiency and acoustic control across critical sectors.

Honeycomb Waveguide Ventilation Boards are essential in EV battery thermal management. Traditional vents create aerodynamic noise (>45 dB at 70 km/h), but waveguide technology:

Reduces wind noise by 15 dB at high speeds

Maintains IP6K9K-rated dust/water protection

Cuts airflow resistance by 40% vs. mesh filters

Example: Tesla Cybertruck battery packs integrate custom waveguide boards for silent cooling.

MRI suites require both massive airflow (500+ CFM) and extreme silence. Honeycomb Waveguide Ventilation Boards deliver:

22 dB noise reduction from 105 dB scanners

Non-ferromagnetic materials preventing image distortion

Antimicrobial coatings meeting ISO 14644 cleanroom standards

Johns Hopkins Hospital reported 30% fewer scan retakes after installation.

Server farms face the "cooling vs. noise" dilemma. Honeycomb Waveguide Ventilation Boards provide:

12 dB noise attenuation at server exhaust points

18% lower fan energy consumption (validated by ASHRAE)

Fire-retardant cores meeting UL94 V-0 certification

Equinix’s Tokyo facility cut cooling costs by $220,000/year using waveguide ventilation.

In aircraft and armored vehicles, Honeycomb Waveguide Ventilation Boards enable:

Radar signature reduction (RCS -15 dBsm)

500°C thermal tolerance in engine bays

Vibration resistance to 50G shock loads

Lockheed Martin integrates them in F-35 electronics bays for stealth ventilation.

High-end offices and studios leverage Honeycomb Waveguide Ventilation Boards to:

Achieve STC 35 sound isolation in HVAC systems

Eliminate 63-250 Hz low-frequency "rumble"

Reduce ductwork length by 60% through wall integration

The Shard skyscraper uses waveguide boards to maintain 28 dB(A) in executive suites.

Factory environments benefit from Honeycomb Waveguide Ventilation Boards through:

Chemical resistance to oils/solvents (NEMA 4X rating)

Spark-proof construction for explosive atmospheres

Washdown-ready IP69K surfaces

Siemens reduced CNC machine downtime by 45% after retrofitting waveguide ventilation.

The era of choosing between airflow and silence is over. Across industries—from life-saving MRI suites to stealth fighter jets, from roaring data centers to whisper-quiet luxury towers—Honeycomb Waveguide Ventilation Boards have emerged as the non-negotiable solution for engineering teams demanding perfection.