To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-07

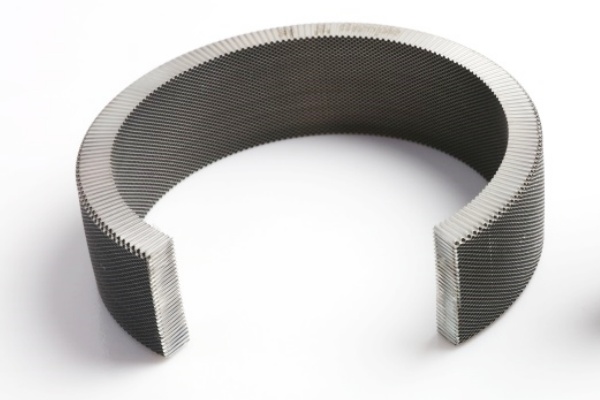

As emission regulations tightened from Euro 3 to Euro 5, honeycomb metal substrate catalytic converters emerged as a pivotal technology in automotive exhaust treatment. Unlike traditional ceramic substrates, these metallic structures combine superior thermal conductivity with mechanical durability, enabling precise control over toxic emissions. This article explores their technical evolution in meeting progressively stringent environmental standards without compromising engine performance.

The honeycomb metal substrate’s thin-wall design (typically 0.05–0.1mm) achieves 30% higher geometric surface area than ceramic equivalents. This maximizes precious metal catalyst dispersion while minimizing backpressure – a critical balance for Euro 4/Euro 5 engines requiring both high flow rates and ultra-low CO/HC/NOx emissions.

FeCrAl alloy substrates withstand rapid thermal cycling (20–900°C in seconds), preventing thermal shock cracks common in ceramics. This ensures consistent catalytic activity during cold starts, where Euro 5 mandates 50% faster light-off than Euro 3.

Euro 3 Compliance: Basic oxidation catalysts (Pd-dominated) sufficed for CO/HC reduction.

Euro 4 Transition: Dual-layer coatings (Pt-Pd/Rh) enabled simultaneous CO/HC oxidation and NOx reduction.

Euro 5 Breakthrough: Tri-metallic (Pt-Pd-Rh) formulations with oxygen storage materials (CeO₂-ZrO₂) achieved >95% NOx conversion under lean/rich cycling conditions.

Micro-channel designs resist ash accumulation, maintaining >90% conversion efficiency after 160,000km – a Euro 5 durability requirement. Aluminum oxide washcoats further prevent sintering of precious metal nanoparticles at high temperatures.

From Euro 3’s focus on basic oxidation to Euro 5’s demand for full-spectrum pollutant control, honeycomb metal substrates have proven indispensable. Their adaptive thermal properties, structural resilience, and catalytic precision set new benchmarks in emission control.