To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-07-29

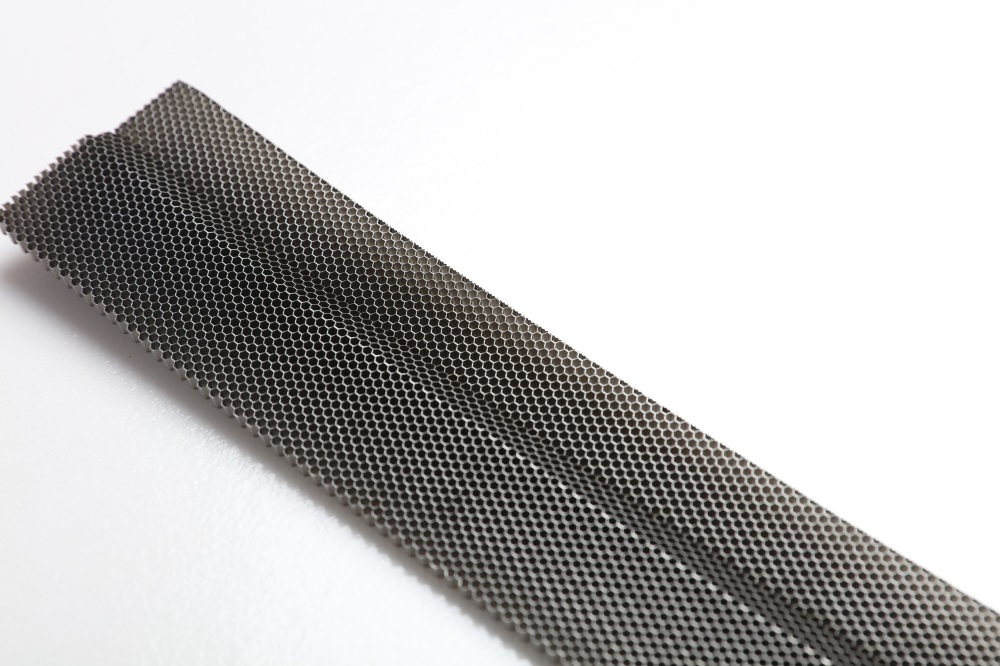

The metal honeycomb substrate has emerged as a transformative component in diesel engine exhaust treatment, addressing the escalating global demands for cleaner combustion technologies. As environmental regulations intensify, this innovative substrate material offers superior thermal stability, mechanical durability, and catalytic efficiency compared to traditional alternatives. This paper examines the evolutionary trajectory, material innovations, and operational benefits of metal honeycomb substrates in contemporary diesel applications.

Modern metal honeycomb substrates represent a paradigm shift in exhaust treatment technology. Manufactured from high-temperature alloys including FeCrAl, these substrates feature:

Ultra-thin wall construction (0.03mm thickness) enabling 400-1400 CPI cell densities

Nano-coating technologies that reduce precious metal loading by 40% while maintaining catalytic activity

Graded cell designs that optimize backpressure and filtration simultaneously

Performance in Emission Control Applications

The substrate's unique properties deliver measurable advantages across key systems:

Diesel Oxidation Catalysts (DOC)

Achieves >95% conversion of CO/HC at temperatures 30% lower than ceramic substrates

Exhibits superior sulfur tolerance (up to 2000ppm) for global fuel variability

Diesel Particulate Filters (DPF)

Captures 98% of PM2.5 while maintaining target backpressure thresholds

Enables passive regeneration at reduced exhaust temperatures

Selective Catalytic Reduction (SCR) Carriers

Maintains 90%+ NOx conversion across 300-500°C operating ranges

Provides precise NH₃ distribution for optimal chemical kinetics

Field studies demonstrate compelling benefits:

40% faster light-off during cold-start conditions

Extended service life exceeding 3000 thermal cycles at 1000°C

Reduced system weight by 25% versus ceramic counterparts

The metal honeycomb substrate stands as a cornerstone technology in the evolution of diesel emission control. As the automotive industry navigates the transition to carbon neutrality, continued advancements in substrate engineering will be instrumental in achieving the next generation of clean diesel solutions. The convergence of material science, manufacturing precision, and system integration promises to unlock even greater potential in emission reduction and fuel efficiency optimization.