To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-02-11

Weight is always limited in aerospace electronics. Extra mass affects payload and system margin. Electronics generate heat. Air must move. Open openings reduce shielding. EMI stability is still required. A Planar Waveguide Vent is used when airflow is needed but shielding cannot be weakened.

Common perforations or louvers allow airflow, but they also form electromagnetic paths. At high frequency, small openings radiate. Interference may enter or escape. In RF-dense avionics, vent areas often become the weak point.

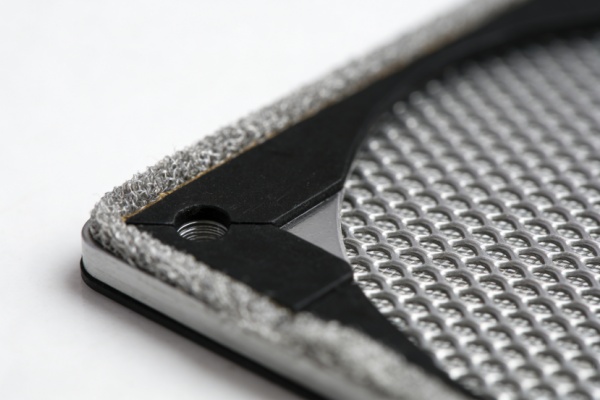

A Planar Waveguide Vent does not behave like an open slot. Air flows through parallel conductive channels. Channel size is kept below cutoff for the operating band. Electromagnetic energy entering the channel attenuates along its depth. Airflow continues with low pressure drop. The vent remains part of the shielding boundary.

Lightweight structure is important. Aluminum alloys are widely used. Low density, good conductivity. Channel walls must be thin for weight, but stiff enough to hold geometry under vibration and temperature change. Small deformation can change attenuation or airflow. Geometry stability matters.

Electrical contact is critical. The vent frame must maintain continuous conductive contact with the enclosure. Gaps, uneven pressure, or oxidation create leakage paths. In practice, interface quality often matters more than channel design. Flatness, fastening, and surface condition must be controlled.

Aerospace environments add stress. Temperature cycling, vibration, pressure variation. Materials expand and contract. Long operation can affect contact and alignment. A properly designed Planar Waveguide Vent keeps airflow and shielding stable across these conditions without adding significant mass.

Design balance is required. Fully sealed enclosures keep shielding but trap heat. Open vents cool better but reduce predictability. A lightweight Planar Waveguide Vent provides controlled airflow and stable EMI behavior. This is why it is commonly used in aerospace electronic enclosures where both weight and EMI stability matter.