To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-02-09

In aerospace work, consistency often matters more than peak numbers. Systems must behave the same under changing temperature, pressure, and operating cycles. Small variations can affect propulsion stability. In catalytic sections, this is where a honeycomb catalyst substrate becomes useful.

Uneven flow creates hot spots and unstable reactions. Packed or irregular structures can produce local differences in velocity and temperature.

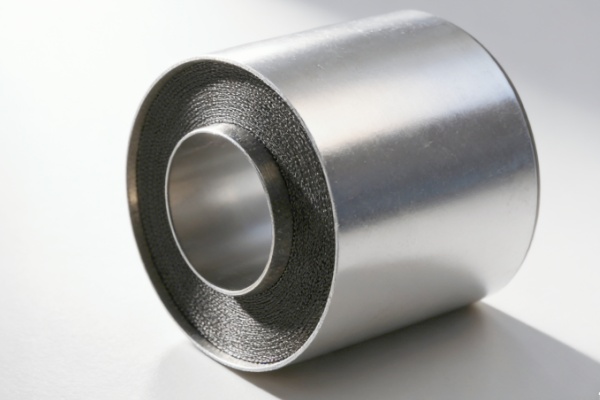

A honeycomb catalyst substrate guides flow through parallel channels. Distribution tends to be more even across the section. Turbulence is lower. Reaction behavior becomes easier to predict.

Pressure drop is tightly managed in aerospace systems. Too high reduces efficiency. Too unstable affects control.

Compared with packed beds, a honeycomb catalyst substrate usually shows more predictable resistance. Straight channels allow engineers to estimate pressure behavior more reliably across operating ranges.

Catalytic decomposition must remain consistent over repeated cycles. Localized overheating or uneven coating can change reaction rate.

With a honeycomb catalyst substrate, internal surfaces are more uniform. Coating tends to distribute more evenly. Reaction behavior becomes steadier, especially under changing thermal conditions.

Aerospace environments include vibration, thermal cycling, and rapid temperature shifts. The catalyst structure must remain intact.

Honeycomb geometry distributes mechanical and thermal stress along continuous walls rather than loose particles. This generally improves structural stability over long operation.

In aerospace design, predictable behavior is often preferred over slightly higher theoretical performance. Systems that behave consistently are easier to control and validate.

The honeycomb catalyst substrate is chosen not only for efficiency, but for stable flow, controlled pressure behavior, and repeatable reaction conditions.

For aerospace catalytic systems, the goal is not maximum reaction rate, but stable and controllable operation. Honeycomb structures help maintain uniform flow, steady pressure drop, and consistent reaction behavior — which is why they are commonly used in aerospace catalyst applications.