To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-02-06

In medical devices, ventilation is rarely just thermal. Many systems sit close to analog front-ends or sensing paths. EMC stability is part of basic reliability. Once you open the enclosure for airflow, the shielding path is no longer continuous. Sometimes the effect is minor. Sometimes it shows up later.

A Planar Waveguide Vent usually enters the discussion only after emissions begin to appear around the vent region.

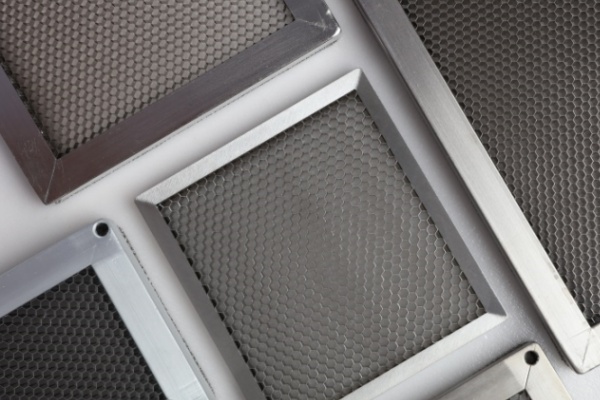

Perforations, louvers, simple mesh — they move air, but they also interrupt the conductive surface. As frequency goes up, even small openings start behaving like leakage paths. The enclosure may look fully shielded, yet scans show energy gathering near the vent.

With a Planar Waveguide Vent, narrow conductive channels attenuate energy along the path while air still passes. The vent stops acting like a gap in the shield.

Medical equipment is expected to behave the same over time. Passing once is not enough. Temperature drift, mounting stress, aging — all of these change things.

In practice, stable channel geometry matters more than peak attenuation on paper. If dimensions hold, the attenuation tends to repeat. That’s why material stiffness, surface condition, and manufacturing consistency get close attention.

Cooling here is usually controlled. Too much airflow can bring noise, contamination risk, or uneven temperature.

Channel length, opening ratio, wall thickness — these are adjusted to keep airflow predictable without weakening shielding. The goal is steady operation, not maximum cooling.

Modern medical systems are compact. Distances between circuits are short. Coupling becomes easier, and vent openings matter more.

When space is tight, adding thicker shielding is not always practical. A Planar Waveguide Vent provides attenuation through geometry rather than bulk, which fits better in dense enclosures.

Medical devices often run near other electronics and monitoring systems. Small, unstable emissions can cause slow, hard-to-trace issues.

Keeping shielding continuous at the vent helps reduce that variability. In many cases, the value of a Planar Waveguide Vent is not just passing EMC, but keeping behavior predictable over long operation.

Once ventilation starts affecting EMC, separating thermal and shielding design rarely works.

A Planar Waveguide Vent doesn’t “add shielding” — it prevents the vent from becoming the weak point.