To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-27

In server racks and data cabinets, cooling problems often show up in specific places. One rack runs hotter than expected. A few modules age faster. Fan speed keeps going up, but temperatures don’t drop evenly.

Two issues are common: local heat buildup and airflow short-circuiting.

Air entering a cabinet doesn’t always move straight through the system. After passing fans, filters, or ventilation panels, the flow can turn, swirl, or hug one side of the enclosure. Instead of reaching all components, part of the air exits too early. This creates hot spots and makes cooling unpredictable.

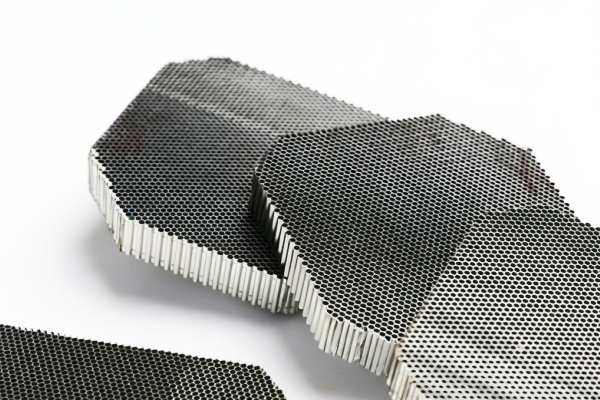

A Honeycomb Straightener is often placed directly behind the air inlet to address this.

The honeycomb structure organizes incoming air before it spreads inside the cabinet. Each small channel limits lateral movement and reduces swirl. As a result, airflow enters the rack in a more uniform direction, rather than breaking into uneven streams.

Once the airflow direction is stabilized, cooling paths become clearer. Air is less likely to bypass components or circulate locally. Heat removal improves across the rack, not just near the inlet or fan area. This helps reduce temperature differences between modules and lowers the risk of localized overheating.

This approach is especially useful in compact data cabinets where space is limited. There is often no room for long ducts or gradual transitions. Organizing airflow right at the inlet becomes the most practical solution.

In server environments, cooling issues don’t always cause immediate failure. More often, they lead to long-term reliability problems and uneven system behavior. Using a honeycomb straightener behind the inlet is a simple way to make airflow more predictable, without increasing fan power or changing the overall layout.