To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2026-01-15

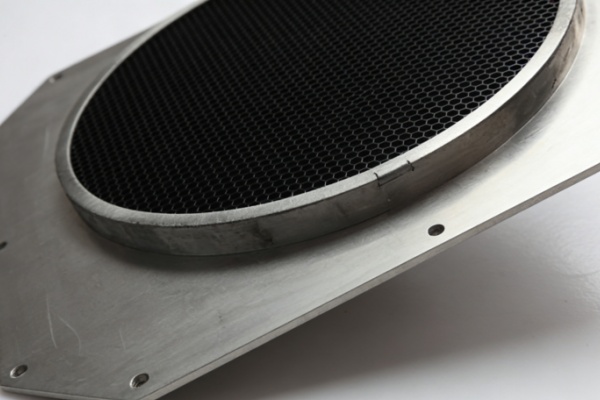

Producing a reliable waveguide window ventilation board is not a single design task.It is a chain of decisions that starts at the drawing stage and only ends when the product is installed and operating in the field.

In practice, most performance issues are not caused by one major mistake, but by small details that accumulate across design, manufacturing, and delivery.

Waveguide window ventilation boards are often specified with target shielding values and airflow requirements. On paper, these targets look clear.

The problem usually appears when assumptions are too ideal. Perfect alignment, uniform pressure, and stable operating conditions rarely exist outside the lab.

A reliable design takes into account manufacturing tolerances, installation variability, and long-term use. This means waveguide dimensions, depth-to-aperture ratios, and frame structures are chosen with margin, not just to meet theoretical limits.

The core of a waveguide ventilation board is its geometry.

Hole size, length, spacing, and layout determine cutoff frequency and airflow resistance. Pushing airflow too far often weakens shielding margins. Pushing shielding too aggressively can create unacceptable pressure drop.

In real projects, balance matters more than optimization. Designs that look slightly conservative on paper tend to perform more consistently after installation.

Material choice is not just about conductivity.

Mechanical strength, corrosion behavior, and surface stability all influence long-term shielding performance. A material that performs well electrically but deforms during installation can cause contact loss at the frame.

Reliable waveguide boards use materials that maintain shape, surface condition, and contact quality over time.

Once the design is fixed, manufacturing becomes the deciding factor.

Waveguide dimensions are sensitive to small deviations. Burrs, uneven edges, or inconsistent hole depth can quietly reduce shielding effectiveness.

Process control matters more than speed. Stable tooling, repeatable machining, and regular inspection help ensure that performance does not vary from batch to batch.

Surface treatment is often treated as a finishing step. In reality, it directly affects grounding and contact resistance.

Coatings that are too thick or applied over contact areas can block electrical paths. Poor adhesion or uneven coverage can lead to oxidation later in service.

Reliable production defines clear contact zones, controls coating thickness, and matches corrosion protection to the actual operating environment.

A waveguide ventilation board does not work alone.

Its performance depends on how it interfaces with the enclosure.

Flatness, frame rigidity, and fastening design determine whether the board maintains uniform contact pressure. Even a well-made board can underperform if the frame flexes or contact points are poorly defined.

Design and manufacturing need to consider the full assembly, not just the board itself.

Visual inspection alone is not enough.

Dimensional checks, surface condition inspection, and contact area verification are key. For critical applications, shielding effectiveness testing is used to confirm that production results match design intent.

The goal of inspection is not just to pass parts, but to catch trends before they become problems.

Damage often happens after production is finished.

Waveguide boards can be bent, scratched, or contaminated during transport if packaging is insufficient. Protective packaging and clear handling instructions reduce the risk of performance loss before installation.

Reliable delivery ensures the product reaches the site in the same condition it left the factory.

Reliable waveguide window ventilation boards are not created by a single advanced process or material.

They are the result of controlled design assumptions, disciplined manufacturing, careful surface treatment, and attention to installation realities.

From design to delivery, every step contributes to whether the board performs as intended when it matters most.