To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-30

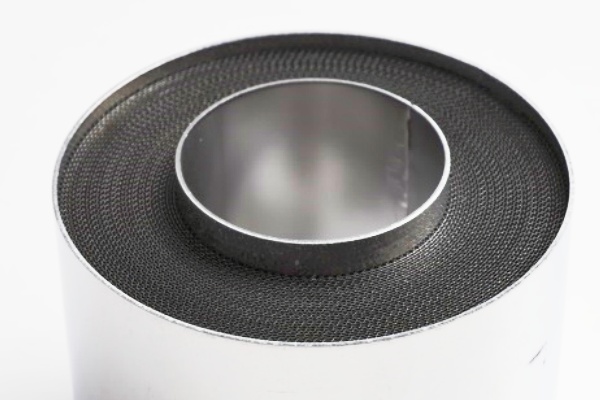

I’ve spent a lot of time working on diesel engines and their converters, and one thing is clear: the substrate matters more than most people realize. Metal honeycomb substrates are at the core of emission control. Exhaust gases hit the substrate, pass through the catalyst coating, and the nasty stuff—CO, HC, NOx—gets converted into carbon dioxide, water, and nitrogen. If the substrate isn’t right, you feel it immediately: uneven flow, higher backpressure, sometimes even engine stutter.

Metal substrates heat up fast, which is critical for diesel engines. Cold-start emissions are a real issue; a substrate that doesn’t reach temperature quickly lets a lot of pollutants escape before reactions even begin. Ceramic ones can handle heat too, but they take longer to light off and are more fragile under vibration. The metal honeycomb structure gives enough surface area for reactions while keeping flow resistance low, which is why it’s used in most modern diesel engines.

The honeycomb itself isn’t just for show. Wall thickness and cell density need to balance durability with flow. Too thick and the engine loses power; too thin and the substrate cracks under thermal cycling. Coatings matter too. Oxidation catalysts deal with CO and HC, while SCR coatings reduce NOx. I’ve seen coatings flake if applied unevenly, and even a tiny spot can reduce efficiency noticeably. Matching the coating to the engine’s exhaust temperature and flow is not optional—it’s what makes the converter work reliably.

Installation is another thing people underestimate. The metal substrate has to sit straight, supported by brackets, with heat shields protecting it from local hot spots. Misalignment, uneven mounting, or vibration can cause cracks in weeks. Exhaust flow has to pass evenly through the substrate, or some channels overheat and degrade. On the shop floor, you notice it immediately when the engine is running—it doesn’t take long to tell if a converter is installed right.

Maintenance is simple in theory but easy to neglect. Look for clogs, cracks, and worn coatings. Diesel engines with heavy loads or frequent thermal cycles are tough on substrates. Replacement requires matching material, geometry, and coating; even a small deviation affects performance. Installed properly, a metal honeycomb substrate keeps the engine running cleaner, reduces backpressure issues, and meets emission regulations.

In short, metal honeycomb substrates aren’t just a passive part—they’re actively shaping how diesel engines perform and how clean they are. The right substrate, coating, and installation make a big difference. Get it wrong, and it shows in exhaust readings, engine feel, and maintenance headaches. On the floor, you live with that every day.