To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-25

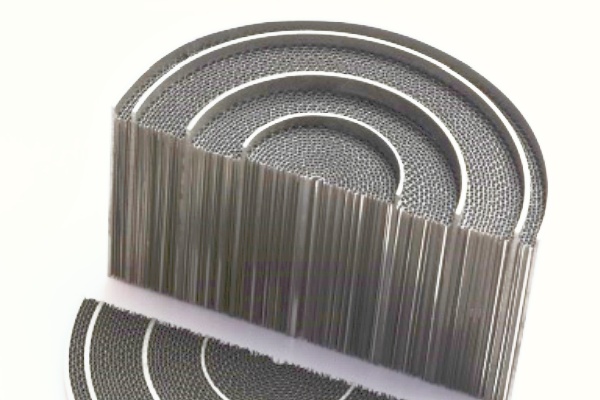

When it comes to catalytic converter replacement, the choice of substrate plays a bigger role than many people realize. In recent years, metallic honeycomb substrate have become a common option, especially for replacement converters used in modern vehicles and high-load applications.

One of the main advantages of a metallic honeycomb substrate is its mechanical strength. Compared with traditional ceramic substrates, metal structures are better at handling vibration and impact. This becomes important in catalytic converter replacement for vehicles that operate under frequent stop-and-go conditions, rough roads, or higher engine output.

Thermal performance is another key factor. Metallic honeycomb substrates heat up faster, which helps the catalytic converter reach operating temperature sooner after engine start. In a catalytic converter replacement scenario, faster light-off can improve emission control during cold starts, where a large portion of total emissions is generated.

Flow characteristics also differ. Metallic honeycomb designs allow for thinner walls while maintaining structural stability. This creates a larger open frontal area, reducing exhaust backpressure. For catalytic converter replacement in performance-oriented or turbocharged vehicles, improved exhaust flow can help maintain engine efficiency without sacrificing emission performance.

Durability over long service cycles is often discussed in replacement applications. Metallic substrates tolerate thermal cycling better, especially in environments with repeated heating and cooling. This makes them suitable for catalytic converter replacement in vehicles that experience varied driving conditions, including short trips, highway operation, and heavy loads.

From a manufacturing and installation perspective, metallic honeycomb substrates offer more flexibility in design. They can be formed into different shapes and sizes, making them easier to integrate into various catalytic converter replacement configurations while maintaining consistent performance.

For these reasons, metallic honeycomb substrate are widely used in modern catalytic converter replacement solutions. Strength, thermal response, flow performance, and durability all contribute to their growing adoption in automotive exhaust systems.