To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-12-01

In the real world, industrial exhaust systems are messy. Conditions aren’t stable, loads change all the time, and nobody is driving under perfect lab settings. Engines work for long hours, sometimes in heat, sometimes in cold, and often under constant vibration. That’s where the Honeycomb Metal Monolith Substrate Catalytic Converter Substrate starts to make real sense.

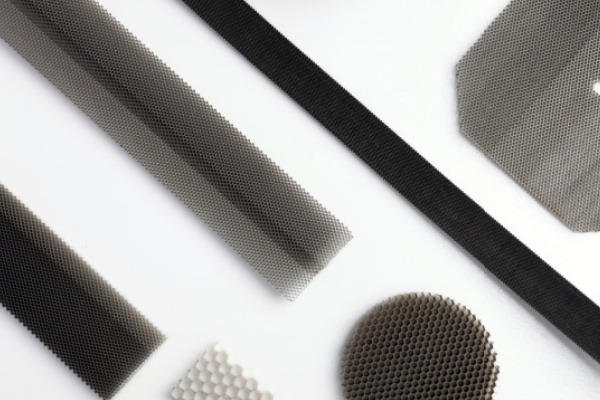

A lot of people only notice the outer shell of a catalytic converter. The part that really does the work is hidden inside. The honeycomb structure, made from extremely thin metal foil, doesn’t look like much at first. But that design is doing more than just filling space. It creates hundreds of small channels for exhaust to pass through while touching as much active surface as possible.

In heavy industrial use, that difference matters. A ceramic substrate may work fine in lighter applications, but once you introduce strong vibration, repeated hot-and-cold cycles, and long working hours, the limits start to show. Micro-cracks turn into real damage. Pieces can break loose. Once that happens, performance drops fast.

Metal handles things differently. The Honeycomb Metal Monolith Substrate Catalytic Converter Substrate can flex slightly without breaking. It tolerates expansion and contraction better. Over time, that small advantage becomes a big one — especially in equipment that can’t just be shut down for repairs whenever there’s a problem.

You see this clearly in power generation. Backup generators, for example, might sit idle for long periods, then suddenly run at full load for hours. That shock in temperature can destroy weaker substrates. Metal, especially Fe-Cr-Al based material, forms a stable oxide layer and just keeps doing its job.

Construction and mining equipment are another good example. These machines are always moving, shaking, and operating on uneven ground. Every bump sends a vibration through the exhaust system. A Honeycomb Metal Monolith Substrate Catalytic Converter Substrate is far more capable of handling that punishment over time without collapsing or cracking.

Even in marine applications, where conditions are constantly wet and salty, metal substrates are becoming the preferred choice. Corrosion, unstable exhaust temperatures, and continuous engine load all push the system hard. Durability stops being a “nice-to-have” and becomes the deciding factor.

One detail people often overlook is warm-up speed. Because metal is thin and conductive, it heats up faster than ceramic. That means the catalyst layer becomes active quicker, and harmful gases start getting converted sooner. For systems that start and stop often, or idling equipment, that early efficiency actually adds up.

From a cost perspective, it’s easy to compare numbers on paper and choose the cheaper option. But over a few years of use, things like downtime, maintenance, replacement, and emission compliance suddenly matter a lot more. In many industrial situations, the Honeycomb Metal Monolith Substrate Catalytic Converter Substrate simply lasts longer and performs more consistently.

That’s why more engineers are choosing it not as a “premium upgrade,” but as a practical solution. Less risk, fewer unexpected failures, and better long-term results. Sometimes, the best material is just the one that keeps working when everything else is being pushed to the limit.