To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-20

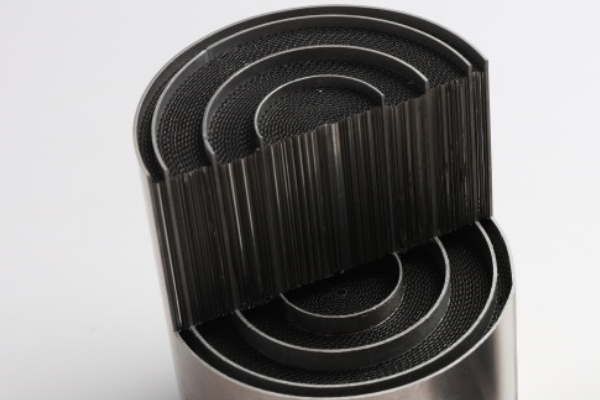

When you start designing a diesel oxidation catalyst (DOC), the metal substrate is one of the first decisions you have to lock in. And despite how simple it looks — just a rolled honeycomb inside a shell — the choice determines almost everything that comes after: pressure drop, light-off behavior, coating quality, vibration durability, and how long the system actually survives in the field.

After working on enough DOC programs, you start to realize there’s no “standard answer.” There are only trade-offs that need to fit the engine, the duty cycle, and the environment the machine works in. Below are the points we usually go through when selecting a metal substrate for a new DOC project.

Before talking about foil thickness or CPSI, the first question is always the same:

What kind of life will this DOC see?

Some projects are easy — light-duty engines, smooth operation, stable temperatures. Others are messy, like construction machines, mining equipment, or anything running full load one minute and idling the next.

Here’s how the environment normally points you toward a material:

High temperature cycles, off-road engines, long idle + sudden load spikes → FeCrAl.

It forms a stable oxide layer and handles constant thermal cycling without deforming.

Moderate temperatures, more predictable operation → 304/316L stainless steel may be enough, especially in cost-sensitive applications.

High humidity, salt exposure, coastal environments → Always lean toward FeCrAl.

Stainless can survive, but long-term corrosion and coating adhesion become concerns.

In many DOC failures, the root cause isn’t the coating or the catalyst. It’s choosing the wrong substrate material for the environment.

A lot of customers assume that a higher CPSI automatically means better conversion. It doesn’t. What high CPSI really means is higher pressure drop, and if your backpressure budget is tight, this becomes a problem fast.

A few practical rules:

100–200 CPSI

Good for low pressure-drop applications, but limited surface area.

300–400 CPSI

The range most DOC metal substrates fall into. Good balance for oxidation reactions.

600+ CPSI

Only makes sense when packaging space is very restricted and backpressure isn’t critical.

Engines are becoming more sensitive to backpressure, especially Tier 4 and Stage V machines. So CPSI is becoming a design decision, not a marketing number.

Foil thickness affects almost everything:

Thin foil (0.03–0.05 mm)

Heats up quickly, boosts light-off, but struggles with vibration and long-term stability.

Thick foil (0.06–0.1 mm)

Better durability, better vibration resistance, slightly slower warm-up.

If the machine sees vibration anywhere near what non-road equipment sees, thin foil becomes a liability. We’ve pulled units from durability benches where thin-foil substrates twisted after only a few hundred hours.

From a pure durability standpoint, round metal substrates are always the most stable. The load distributes evenly, the shell welds don’t concentrate stress, and vibration tends to settle rather than amplify.

Oval or rectangular shapes aren’t wrong — they’re packaging solutions. But you pay for them in durability and vibration sensitivity.

Whenever space allows, round is simply the safest choice for a DOC.

Many coating issues get blamed on the washcoat. In reality, most start earlier:

inconsistent channel geometry

corrugation drift

foil tension problems

shell deformation during welding

surfaces not cleaned or prepared evenly

Good substrates produce good coated parts. Poor substrates may coat nicely at first but fail after a few hundred hours of thermal cycles. FeCrAl, for example, provides better adhesion after oxidation. Stainless steel needs nearly perfect pre-treatment to avoid long-term peeling.

This is the part spec sheets never mention.

Two factories can use the same foil, same CPSI, same shell, and still produce substrates that behave completely differently in an engine. Why?

Because consistency depends on:

corrugation accuracy

winding alignment

brazing temperature control

weld penetration and distortion

coating preparation steps

If these vary, your DOC performance will vary too.

In real engine programs, repeatability matters as much as material selection. Sometimes more.

Selecting the right metal substrate for a DOC project isn’t just comparing numbers on a drawing. It’s understanding how the engine behaves, what environment it lives in, and how the substrate will respond after thousands of heat cycles and vibration hours.

If you get the substrate right, the DOC usually behaves exactly as designed. If you get it wrong, even the best catalyst can’t fix the problem.