To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-10-16

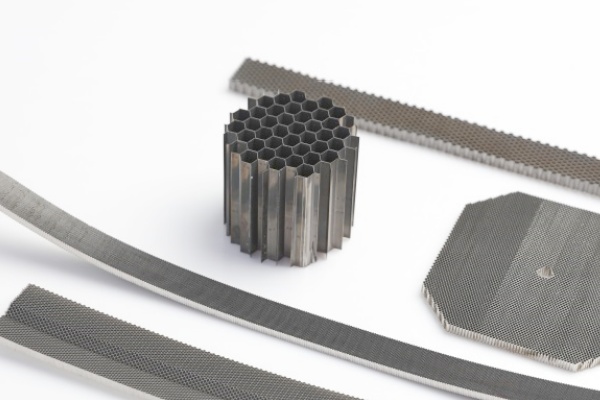

When people talk about improving water jet cutting quality, most think about pressure, nozzle size, or pump performance. But those who’ve spent enough time around cutting tables know another truth — the platform under your material matters just as much. The Water jet machines honeycomb platform isn’t just there to hold things up; it shapes how clean the cut looks, how long your equipment lasts, and even how stable the whole process feels.

The Water jet machines honeycomb platform is designed with a simple purpose: to support your material while letting high-pressure water and debris pass through freely. The open structure reduces splashback and helps keep the surface clean. But not all honeycomb designs work the same way — choosing the right one depends on what you’re cutting and how often you’re running your machine.

For thin or soft materials, like glass, rubber, or foam, a fine-cell Water jet machines honeycomb works best. It gives even support, keeps vibration to a minimum, and prevents the edges from getting damaged. When the grid is tighter, the workpiece stays flat and steady, which is key for precision cuts.

If you’re cutting thicker metals or harder materials, a coarser honeycomb structure usually performs better. The larger cells let the water and waste escape more easily, reducing clogging and keeping the cutting stream consistent. This also helps extend the life of your Water jet machines honeycomb platform since there’s less trapped grit wearing it down over time.

Material choice for the platform also plays a role. Stainless steel honeycomb structures handle long hours and harsh conditions well — they resist rust and deformation. Aluminum ones, on the other hand, are lighter and easier to move around, making them handy for shops that switch setups often.

Whatever material you choose, regular cleaning is a must. Bits of leftover material, sand, and residue can slowly warp the surface and affect cutting accuracy. Many seasoned operators make it a habit to clean the Water jet machines honeycomb every few shifts — it’s a small task that saves headaches later.

At the end of the day, selecting the right Water jet machines honeycomb platform is about knowing your own process — what materials you cut, how precise you need to be, and how much maintenance you’re willing to do. Once the platform fits the job, you’ll notice smoother edges, less downtime, and a longer-lasting machine. It’s one of those behind-the-scenes upgrades that quietly make a big difference.