To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-27

Most people connect the idea of a Purification catalytic converter with cars, but in reality, it plays a big role in industry too. Power plants, chemical factories, and steel mills all rely on this kind of technology to keep their exhaust cleaner and meet today’s emission rules.

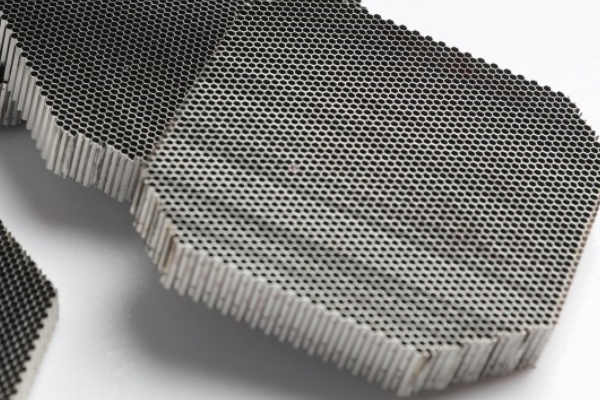

Take a power plant for example. Burning fuel produces a mix of carbon monoxide, hydrocarbons, nitrogen oxides, and fine particles. Without treatment, these gases would head straight into the atmosphere. A Purification catalytic converter steps in here, using its honeycomb-shaped substrate coated with active materials to convert those pollutants into less harmful gases like carbon dioxide, nitrogen, and water vapor. The honeycomb design is no accident—it allows exhaust to flow through easily while giving plenty of surface area for the reactions to happen.

Chemical plants face a slightly different problem. Many processes release volatile organic compounds and other reactive gases. A Purification catalytic converter can handle those by oxidizing or reducing them before they leave the stack. This not only keeps the plant compliant but also cuts down on local air quality issues that neighbors would otherwise notice.

Steel production is another area where these converters prove their worth. High-temperature furnaces give off exhaust streams rich in carbon monoxide and hydrocarbons. With a well-designed Purification catalytic converter, plants can bring those emissions under control while keeping operations running safely.

What makes this technology especially useful in industry is its adaptability. A Purification catalytic converter can be tailored with different coatings and substrates depending on what the exhaust looks like and how hot it runs. That flexibility means it works across a wide range of applications, from large boilers to specialized process units.

With emission standards tightening worldwide, the Purification catalytic converter is becoming more than just an automotive component. It’s turning into a cornerstone for cleaner power generation, safer chemical production, and more sustainable heavy industry.