To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-16

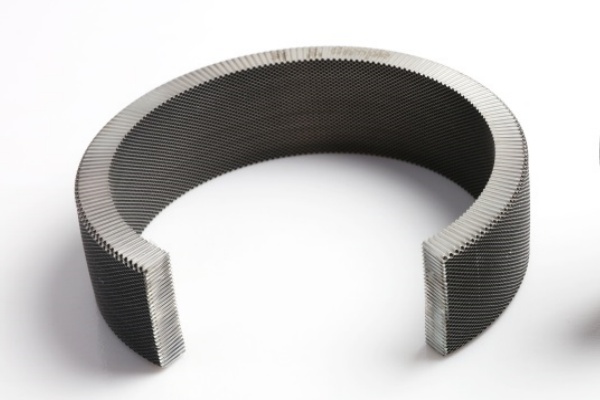

Anyone who has worked around a wind tunnel knows that the airflow going in is rarely perfect. It often carries swirls, uneven speed, and small bursts of turbulence. If you run a test in that condition, the numbers won’t stay steady. That’s why a Wind tunnel Honeycomb flow straightener makes such a difference.

When you don’t use one, the test section ends up with unstable flow. The model might see irregular forces, drag values can jump around, and pressure readings are harder to trust. Even small shifts in flow direction are enough to throw off the data.

With a Wind tunnel Honeycomb flow straightener, the situation changes right away. The honeycomb channels break down cross-flows and smooth out the stream. The result is air that runs straight and even, with much lower turbulence. Measurements become more repeatable, and you can actually rely on the numbers.

In practice, this shows up clearly. For example, in a car tunnel test, drag values without a flow straightener may keep bouncing up and down. Put the honeycomb in, and the values settle, giving engineers a clear picture of what’s really happening. The same applies in aircraft testing, where cleaner flow directly improves the accuracy of lift and drag data.

The takeaway is simple: accurate tunnel data depends on controlled airflow. AWind tunnel Honeycomb flow straightener may look like just a block of cells, but it’s what makes the test conditions stable and the results worth trusting.