To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-09-12

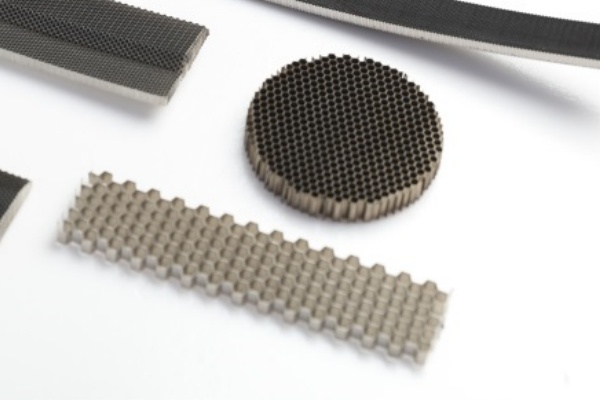

In water treatment and cutting systems, many parts work quietly in the background. One of them is the water jet machines honeycomb. At first glance, it’s just a grid of small channels, but in reality, this simple structure makes a big difference to how the whole system performs.

The first job of a water jet machines honeycomb is to keep water moving evenly. In tanks, flotation units, or biofilters, flow balance is everything. If water slows down or gathers in certain spots, efficiency drops. The honeycomb spreads the flow, so every part of the system gets the same treatment.

Another benefit is that it creates more contact area. In aeration towers, oxidation tanks, or cooling systems, the more surface water has to meet air, the better the results. The honeycomb gives that extra area, which helps oxygen transfer and speeds up reactions.

It also acts as a solid support. In filtration systems or biofilm reactors, filters and membranes need a backbone to hold them steady. The water jet machines honeycomb provides that support, preventing media from bending or collapsing. Without it, the system wouldn’t stay reliable for long.

And there’s one more thing—it helps save energy. A well-designed water jet machines honeycomb keeps pressure loss low. With the right size and thickness, water flows through with less resistance, meaning pumps don’t have to work as hard. Over time, that cuts down on energy costs.

The water jet machines honeycomb might not be the most noticeable part of a system, but it plays a role in nearly every step: keeping water flow steady, improving treatment, supporting filters, and reducing power use. It’s a quiet contributor, but without it, efficiency would take a serious hit.