To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-29

Walk through any facility working on emission control systems today, and you'll likely hear engineers talking about metal substrate oxidation catalysts. Having worked with these systems for years, I've seen how they're transforming what's possible in catalytic oxidation—not just in theory, but in real-world applications where performance and reliability matter.

The honeycomb structure of these catalysts isn't just for show—it's where the magic begins. I've watched technicians handle these substrates under microscopes, marveling at how the intricate network of channels creates massive surface area in such compact form. This expanded surface isn't just numbers on a spec sheet; it translates directly to more active sites for reactions to occur, making the entire system more efficient from the start.

What really surprises many engineers is how these metal substrates handle flow resistance. The thin walls and open structure significantly reduce pressure drop compared to traditional options. I've seen installations where this single advantage changed entire system designs, allowing for smaller fans and lower energy consumption—something that looks great both technically and economically.

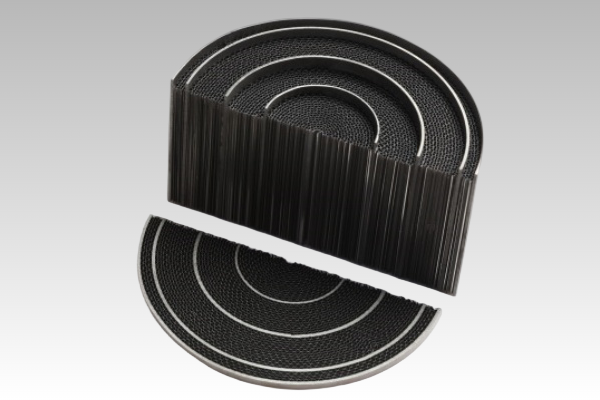

The flexibility in design continues to impress me. Unlike their ceramic counterparts, metal substrate oxidation catalysts can be fabricated into various shapes and sizes. I've worked on projects where circular designs solved space constraints in rotary reactors, and large rectangular panels enabled scale-up that would have been impossible with other materials. This adaptability makes them invaluable for custom applications where off-the-shelf solutions won't cut it.

Durability is where these catalysts truly shine. I remember visiting a installation that had been running for three years in a high-vibration industrial setting. When we inspected the metal substrate oxidation catalysts, they showed minimal degradation despite the challenging conditions. That kind of reliability changes how plants approach maintenance schedules and system longevity.

The heart of these systems lies in the partnership between metal support and catalytic materials. I've spent hours with researchers discussing how precious metals like platinum and palladium interact with oxide coatings at the molecular level. These interactions do more than just create active sites—they help maintain performance over time by preventing the active components from degrading or sintering together.

What many don't appreciate is how these catalysts handle real-world variability. In one installation I worked on, temperature fluctuations that would have damaged ceramic substrates didn't faze the metal-based system. This resilience comes from the metal's ability to expand and contract uniformly under thermal stress, maintaining structural integrity through cycles that would destroy other materials.

The environmental applications particularly excite me. I've seen metal substrate oxidation catalysts installed in systems cleaning everything from industrial exhaust streams to commercial kitchen emissions. Their ability to work effectively at lower temperatures makes them ideal for applications where energy conservation matters as much as emission control.

As we look toward future applications, the flexibility of metal substrate oxidation catalysts opens new possibilities. Researchers are exploring uses in chemical synthesis, energy conversion, and even air purification systems that simply weren't practical with previous technologies. The ability to customize shape, size, and catalytic formulation makes these systems incredibly versatile.

What ultimately makes metal substrate oxidation catalysts so compelling isn't any single feature, but how all these advantages work together. The durability enables longer service life, the efficiency reduces operating costs, and the flexibility allows for solutions tailored to specific challenges. It's this combination that's driving their adoption across so many industries today.

Having watched these systems evolve from laboratory curiosities to industrial workhorses, I'm convinced they represent more than just incremental improvement. They're enabling approaches to oxidation catalysis that simply weren't possible before, and that's why they're becoming the solution of choice for engineers facing tough oxidation challenges.