To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-28

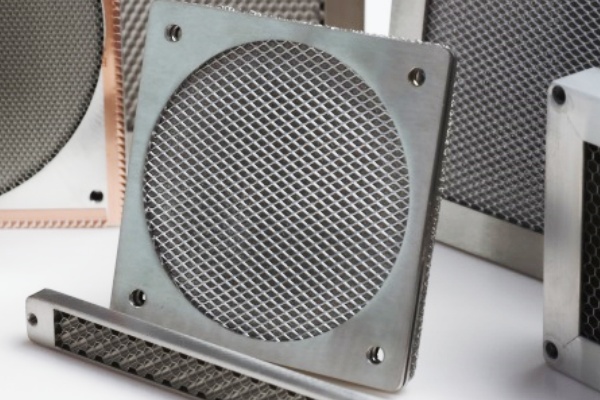

Finding the right plane wave shielding ventilation board can feel overwhelming with all the technical specifications to consider. Through my experience working on various electronic enclosure projects, I've learned that the selection process comes down to balancing a few key factors that directly impact performance and reliability.

The first thing I always consider is shielding effectiveness.

I remember working on a medical imaging equipment project where we needed at least 80 dB of attenuation at specific frequency ranges. The plane wave shielding ventilation board we selected had to meet these precise requirements while still allowing adequate airflow. It's not just about picking the highest shielding number—it's about matching the specification to your actual operational environment and the sensitivity of your components.

Airflow requirements often become the balancing act in selection.

I've seen designers get so focused on shielding that they forget about cooling needs. On one telecom project, we calculated the required CFM based on heat dissipation needs first, then found a plane wave shielding ventilation board that could deliver both the airflow and necessary EMI protection. The hexagonal pattern design we chose provided an excellent compromise between open area and shielding performance.

Environmental factors will make or break your selection.

Early in my career, I learned this lesson the hard way when a beautifully specified plane wave shielding ventilation board failed prematurely in a coastal environment. Now I always check IP ratings and corrosion resistance specifications carefully. For outdoor applications, I typically recommend boards with additional protective coatings, even if they cost slightly more upfront.

The physical installation aspects are where many projects encounter surprises.

I've arrived at sites where the plane wave shielding ventilation board technically met all specifications but couldn't be properly installed due to space constraints or mounting compatibility issues. Now I always request samples early in the design process to verify mounting dimensions and ensure our enclosure design can accommodate the required compression for proper EMI sealing.

Material choice matters more than many engineers realize.

Different alloys offer varying balances of conductivity, weight, and corrosion resistance. For most applications, aluminum provides the best combination of performance and cost-effectiveness, but I've specified copper-based boards for projects where maximum conductivity was critical, despite the higher cost.

The operating environment dramatically affects selection criteria.

I've specified plane wave shielding ventilation board for everything from benign office environments to harsh industrial settings. Each environment brings different challenges—temperature extremes, chemical exposure, vibration, and particulate contamination all influence the final selection.

What many engineers don't realize is that proper installation is just as important as product selection.

I've seen excellent plane wave shielding ventilation boards underperform because of poor installation practices. Ensuring clean mounting surfaces, proper gasket compression, and correct fastener torque makes a significant difference in actual shielding performance.

Long-term maintenance considerations should influence your selection.

I prefer designs that allow for cleaning and inspection without compromising the shielding integrity. Some board designs incorporate features that facilitate maintenance while maintaining their protective capabilities throughout the product lifecycle.

The selection process ultimately involves balancing competing priorities.

I often create simple scoring systems that weight factors based on their importance to the specific application. This approach helps teams make objective decisions when comparing different plane wave shielding ventilation board options and ensures we don't over-specify for less critical applications.

Through years of specifying these components, I've learned that the best choice isn't always the most expensive or highest-performing option on paper. It's the plane wave shielding ventilation boardthat provides the right balance of performance, reliability, and cost for your specific application needs.