To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-08-02

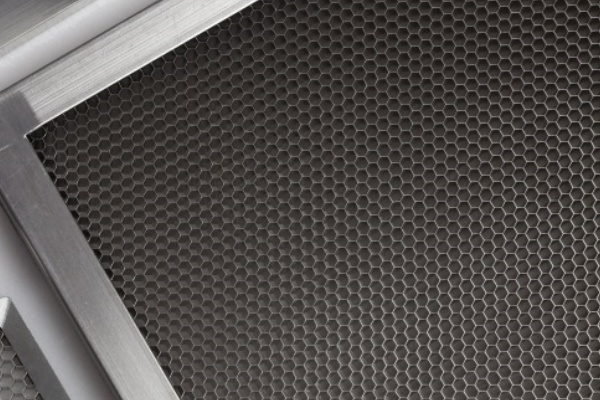

Modern electronics face two relentless enemies: relentless heat generation and pervasive electromagnetic interference (EMI). Conventional cooling solutions—like fans or simple vents—leave systems vulnerable to disruptive signals, while fully sealed enclosures risk dangerous overheating. This is where the ventilation waveguide vents proves indispensable. By leveraging the physics of cutoff waveguides, these specialized components allow cool air to flow freely while blocking electromagnetic waves across critical frequencies—acting as both a thermal escape route and an electromagnetic shield. Their unique design isn’t just useful; in many advanced technologies, it’s non-negotiable.

5G/6G Base Stations & Microwave Equipment

As networks advance toward higher frequencies (mmWave and beyond), base stations generate intense heat while becoming hypersensitive to EMI. Traditional mesh vents fail to shield against high-frequency interference, causing signal distortion and dropped connections. Here, waveguide vents are essential—their honeycomb structure provides airflow with >100 dB shielding effectiveness at frequencies up to 10 GHz, ensuring signal purity in densely deployed urban nodes.

Data Center Server Racks & Network Cabinets

A single server rack can dissipate 10+ kW of heat, yet electromagnetic “crosstalk” between densely packed units risks data corruption. Waveguide vents integrated into cabinet doors enable efficient airflow while maintaining >60 dB EMI isolation, preventing bit errors in financial, cloud, or AI infrastructure. Without them, compromising on cooling or security becomes inevitable.

Military & Aerospace Electronics

Radar systems, electronic warfare suites, and avionics operate in EMI-saturated environments where failures threaten lives. Military standards (like MIL-STD-285) mandate extreme EMI resistance. Waveguide vents meet this while surviving harsh conditions—shielding aircraft communication from jamming or ensuring missile guidance systems resist interference. Their all-welded, lightweight variants are preferred for airborne use, where reliability outweighs cost.

Emergency & Defense Mobile Units (e.g., Medical/Armored Vehicles)

Field-deployed units like military field hospitals or command vehicles use electronic systems in electromagnetically hostile zones. Waveguide vents in these mobile shelters block external EMI (e.g., from radar or jammers) while venting heat from power-hungry equipment. Crucially, they also prevent internal signals from leaking—a vital feature for covert operations.

Medical Imaging & Precision Diagnostics

MRI machines generate powerful magnetic fields (3+ Tesla) and require stringent EMI containment. Stray signals distort scans, while heat from gradient coils demands active cooling. Waveguide vents are integrated into shielded rooms to maintain ≤0.5 ppm field uniformity—a non-negotiable for diagnostic accuracy. Similarly, linear accelerators in radiation therapy rely on them for both safety and precision.

Industrial Automation & Control Systems

Factories using high-frequency drives (e.g., for robotics or motors) face EMI-induced malfunctions. Waveguide vents on control cabinets suppress interference from nearby equipment while exhausting heat from PLCs and drives. In mining or oil/gas operations—where explosive gases exist—they also prevent sparks, combining safety with resilience.

Mining Cabins & Ruggedized Outdoor Equipment

Mineral exploration cabins house sensitive electronics amid high-power machinery emitting intense EMI. Research confirms that inclined waveguide vents (at 45°–60°) boost shielding by >10 dB through multi-path signal attenuation while preventing dust/rain ingress—proving critical in remote mining sites where downtime costs escalate rapidly.

Waveguide ventilation vents operate silently at the intersection of thermodynamics and electromagnetics—often overlooked but fundamentally enabling progress. In 5G towers, they maintain signal integrity; in surgical suites, they protect lifesaving scans; in satellites, they ensure unfailing communication. As electronics grow denser and frequencies soar, their role will only expand.