To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-07-18

In environments requiring strict Electromagnetic Shielding, such as data centers, military facilities, and medical equipment, maintaining proper ventilation and heat dissipation is critical. Traditional shielding methods often block airflow, leading to overheating. A waveguide window offers a balanced approach by leveraging the principles of cutoff frequency to block unwanted electromagnetic interference (EMI) while permitting air circulation.

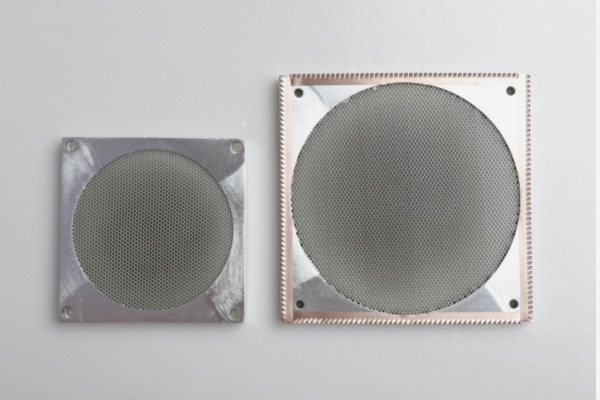

The waveguide window operates on the cutoff waveguide theory, where electromagnetic waves below a certain frequency are attenuated, ensuring Electromagnetic Shielding. The most common design uses a honeycomb structure composed of hexagonal cells. This configuration provides sufficient open area for ventilation and heat dissipation while maintaining shielding effectiveness. The length and diameter of each waveguide cell are carefully calculated to ensure optimal performance.

To enhance durability and shielding, waveguide windows are typically made from conductive metals such as aluminum or steel. A conductive coating, such as nickel or tin plating, is often applied to improve electrical continuity and corrosion resistance. The honeycomb structure is designed with slight inclinations (15-45 degrees) to improve resistance to rain and environmental exposure without requiring additional protective covers.

Proper installation is crucial for maintaining shielding integrity. The waveguide window must be securely mounted with conductive gaskets or welded connections to prevent electromagnetic leakage. In applications where ventilation and heat dissipation are priorities—such as in high-power electronic enclosures—the waveguide window ensures that airflow is not restricted while still meeting stringent EMI shielding requirements.

The waveguide window is a versatile solution for environments requiring both Electromagnetic Shielding and effective ventilation and heat dissipation. By combining advanced structural design with conductive materials, it addresses the challenges of thermal management and interference protection. Future developments may further optimize waveguide geometries and materials to enhance performance in demanding applications.