To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-10-09

If you’ve spent time around water jet machines, you’ll know the cutting head isn’t the only part that matters. The table under your workpiece — especially when it’s a Water jet machines honeycomb — can decide whether your cut turns out clean or messy. It’s one of those things that looks simple, but once you’ve worked with it, you realize how much it affects the final result.

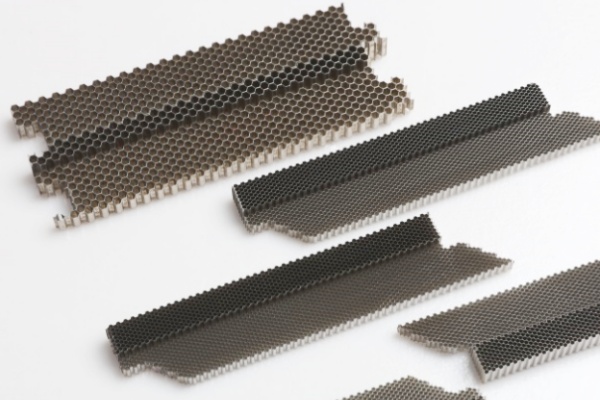

In high-pressure cutting, even the smallest vibration can mess up the edge. The Water jet machines honeycomb helps by giving the workpiece a solid, stable surface without blocking the water flow. Those tiny hexagonal cells spread the pressure evenly and keep everything still, even when the jet is blasting at full power. It’s a smart way to balance support and flow — enough contact to hold, enough space to let the jet pass cleanly through.

Another big reason the Water jet machines honeycomb works so well is how it handles shock. When the jet hits, the structure absorbs and spreads out the impact instead of letting it bounce back into the material. You’ll notice this especially when cutting thin metals, glass, or composites — fewer vibrations mean straighter cuts and fewer cracks.

It also helps with keeping the platform clean and flat. Over time, debris and worn parts can throw off the cutting height. The honeycomb sections are easy to replace or clean, so the table stays even and consistent. That’s a small detail, but anyone who’s done long production runs knows how much uneven support can ruin precision.

At the end of the day, the Water jet machines honeycomb isn’t just a piece of the table — it’s part of the cutting system. It makes the process smoother, extends machine life, and helps you get better results with less tuning. Once you’ve worked with a well-designed one, you won’t go back.