To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-07-02

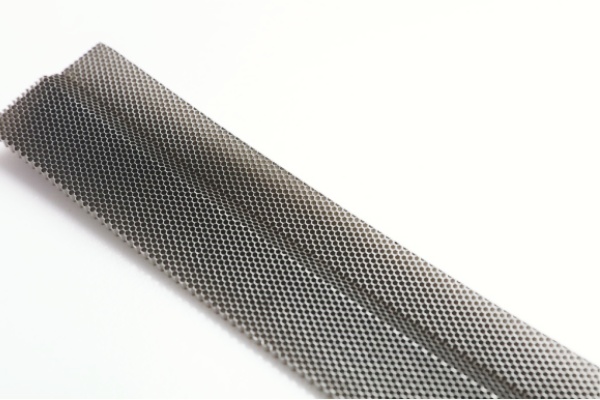

The Metal Honeycomb Substrate for desulfurization and denitrification represents a breakthrough in air pollution control technology. Its innovative design combines structural efficiency with remarkable durability, addressing critical challenges in industrial emission treatment processes across power plants, refineries, and chemical facilities.

The honeycomb channel architecture of Metal Honeycomb Substrate for desulfurization and denitrification demonstrates exceptional engineering precision. With cell densities adjustable between 200-600 cells per square inch (cpsi), it achieves optimal gas flow distribution while maintaining structural integrity. The ultra-thin walls (0.05-0.2mm thickness range) maximize surface area without compromising mechanical strength. Notably, the open frontal area exceeding 85% ensures minimal flow resistance, a crucial factor in large-scale operations.

Thermal resilience distinguishes Metal Honeycomb Substrate for desulfurization and denitrification from conventional alternatives. Capable of withstanding continuous operation at 800°C, it outperforms many ceramic counterparts in high-temperature scenarios. The substrate maintains pressure drop below 500Pa/m even under heavy particulate loading, significantly reducing energy consumption. Its thermal shock resistance (>100 thermal cycles) guarantees reliable performance during frequent start-ups and shutdowns, a common requirement in industrial operations.

The Metal Honeycomb Substrate for desulfurization and denitrification establishes new benchmarks in emission control technology through its harmonious combination of structural intelligence and performance reliability. As environmental regulations become increasingly stringent globally, these substrates will continue to evolve, offering enhanced solutions for cleaner industrial processes while maintaining operational efficiency and cost-effectiveness.