To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2023-09-30

In September, Maanshan MAT Aviation Manufacturing Co., Ltd. passed PRI's Nadcap special process audit for Nonconventional Machining (NM) and obtained the qualification certificate.

The special process NM audit includes ELECTRICAL DISCHARGE MACHINING (EDM) and SPARK EROSION GRINDER (SEG).

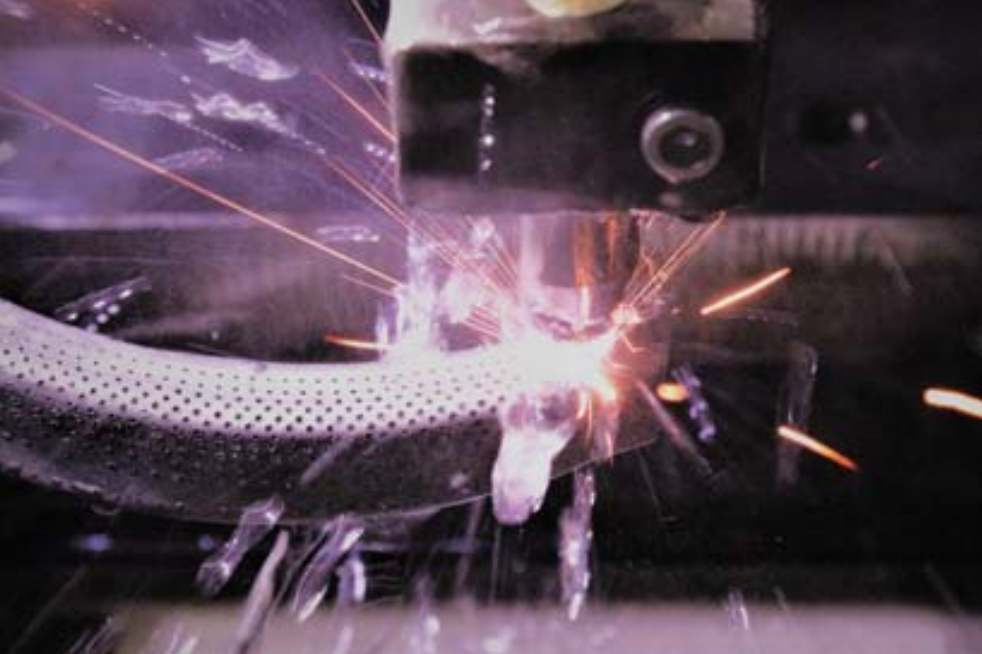

EDM machining is a process method that uses the electrical corrosion phenomenon between the positive and negative electrodes of high-frequency pulsed current to erode excess metal from the workpiece. EDM processing is divided into wire EDM (also known as wire cut) and EDM (also known as sink EDM). Wire EDM is mainly used for the processing of a single view of a certain contour on the workpiece, and EDM can process multiple contour profiles in space at the same time. EDM processing technology has been widely used in the production of machinery and automobiles, aerospace, petrochemical, light industry and electronics industries, such as mold processing, precision parts processing, special material parts processing, micro (deep groove narrow slit) processing, etc.

SEG die-sinking equipment is another EDM system, which completes the machining requirements for the size and shape of the product by performing arc grinding processing of metal parts under EDM through rotating electrodes to remove the product material. SEG machining is mainly suitable for honeycomb products, which allows the grinding of complex structural products and the finished product after grinding is clean and free of obvious burrs compared to traditional grinding.

Up to now, the company has obtained NADCAP certification for brazing heat treatment (HT), welding (EBW&TIG), non-destructive testing (RT&PT), NM (EDM&SEG) and other processes, and has reached a new level in special process management. As a specialized manufacturer of turbo parts, Maanshan MAT will provide customers with more reliable and high-quality products and services based on the current qualifications and the continuous improvement of internal quality management level, and continue to create more value for customers.