To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-06

Diesel engines are getting cleaner, and a big part of that story is happening inside a component no bigger than your forearm: the metal honeycomb substrate. Here's a closer look at how this technology works and why it matters.

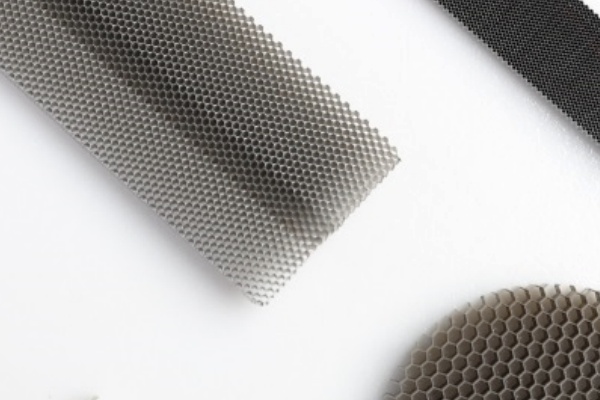

At the core of modern exhaust treatment sits a stainless steel cylinder filled with thousands of microscopic channels. This honeycomb structure isn't just about looking interesting – it's carefully engineered to solve two competing needs. The straight, parallel channels let exhaust gases flow through with minimal resistance, protecting engine performance. Meanwhile, the vast network of channel walls provides the perfect real estate for the chemistry that cleans up emissions.

The magic is in the numbers. By packing more and smaller channels into the same space, engineers have dramatically increased the available surface area. We're talking about a postage stamp-sized area that, when you count all the channel walls, unfolds into a football field of active surface. This massive area is crucial because it gives exhaust gases maximum exposure to the catalyst coating that transforms pollutants into harmless substances.

That brings us to the coating – a sophisticated washcoat that bonds to the metal channels. This is where the actual cleaning happens. The coating contains precious metals like platinum and palladium that act as catalysts, breaking down nitrogen oxides, carbon monoxide, and unburned hydrocarbons without being consumed in the process. Getting this coating just right – ensuring it sticks properly and maintains its effectiveness through years of heat cycling – has been one of the major engineering challenges we've overcome.

Diesel environments are tough. Temperatures can swing hundreds of degrees in minutes, and vibrations are constant. This is where metal substrates prove their worth. Unlike earlier ceramic versions, metal honeycombs can handle the thermal shock without cracking. They also heat up faster from a cold start, which means they begin cleaning emissions sooner – a crucial advantage given that much of an engine's pollution output occurs during those first few minutes of operation.

The evolution continues. We're seeing substrates with even higher cell densities and advanced coating formulations that work better at lower temperatures. For engine manufacturers and fleet operators, this translates to more effective emission control with less impact on fuel economy.

Our engineering team has been working with these substrates through several generations of emission standards. If you're evaluating aftertreatment options for your next project, we'd be happy to share what we've learned about making these systems work in real-world conditions.