To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-05

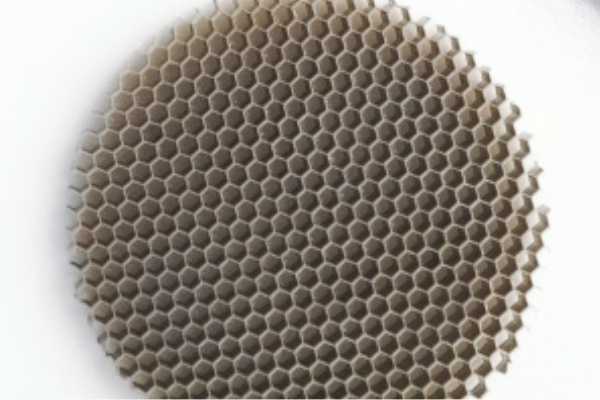

Producing a round metal substrate is not just about forming metal into a circular shape — it’s about ensuring that every piece leaving the factory can perform reliably under real industrial conditions. These components often end up in catalytic converters, heat exchangers, or other systems that face constant temperature stress. That’s why a strong focus on quality control is absolutely essential throughout the production process.

Everything starts with the raw material. The metal strip used for a round metal substrate — usually stainless steel or FeCrAl alloy — needs to have the right balance between flexibility and high-temperature resistance. Before any forming begins, materials are checked for surface uniformity, coating compatibility, and proper alloy composition. Skipping this step could lead to premature oxidation or warping once the substrate is in operation.

When the forming process begins, dimensional accuracy becomes the key concern. A round metal substrate has to maintain a near-perfect geometry; even a small deviation in thickness or roundness can affect how gas flows through the channels later on. In most production lines, operators rely on laser gauges or micrometers to spot inconsistencies early rather than wait for final inspection.

Welding and joining steps bring their own challenges. Because the round metal substrate must endure repeated thermal expansion, every weld line and seam has to be clean, precise, and stress-free. Skilled technicians often perform visual inspections and sometimes use ultrasonic testing to make sure no hidden voids or weak spots remain.

Surface inspection is another critical area that doesn’t get enough attention outside of the factory floor. A scratch or small dent might look harmless, but after hundreds of heat cycles, that same imperfection can become a corrosion site. To prevent this, each round metal substrate is carefully checked under strong lighting and sometimes even under microscopes, depending on the product grade.

Once the catalytic coating is applied, the real test begins. Coating adhesion, thickness uniformity, and coverage are all verified. A poor coating bond means reduced catalytic activity and a shorter service life, so technicians perform adhesion pull tests or sample destructive testing on random units. It’s better to lose one piece in testing than risk a batch failure in the field.

Thermal cycling tests are another standard part of the inspection routine. The round metal substrate is repeatedly heated and cooled to mimic the real conditions it will face. The goal is to make sure no cracking, warping, or coating delamination occurs. Units that fail these tests are immediately flagged for review, and the production parameters are adjusted if needed.

Cleanliness is also more important than many realize. Any trace of oil, dust, or metal residue can affect the catalytic coating or the substrate’s bonding performance. So before final assembly, every round metal substrate is cleaned, dried, and checked again — often with both visual inspection and wipe tests.

Finally, every unit gets logged with a serial code and inspection record. This traceability system allows engineers to track performance data and material history long after the product has been shipped. It’s part of building long-term reliability and accountability into the manufacturing process.

In short, producing a round metal substrate that meets industrial standards takes more than precision machines — it takes experience, consistency, and strict inspection discipline. Every check, from material to final packaging, adds another layer of assurance that the product will perform as expected once it’s out in the field.